Plant operator

Other denominations

Process Operator or Process Technician

Description

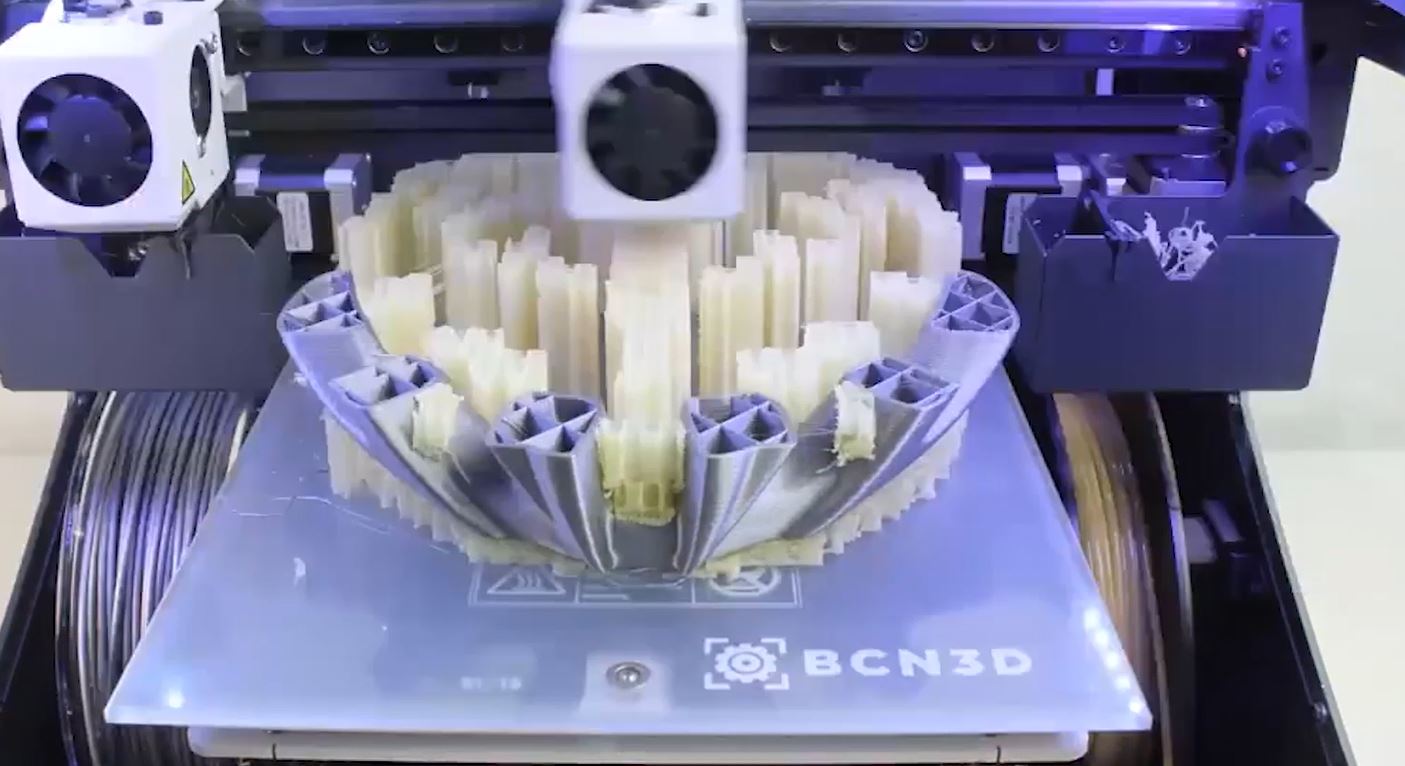

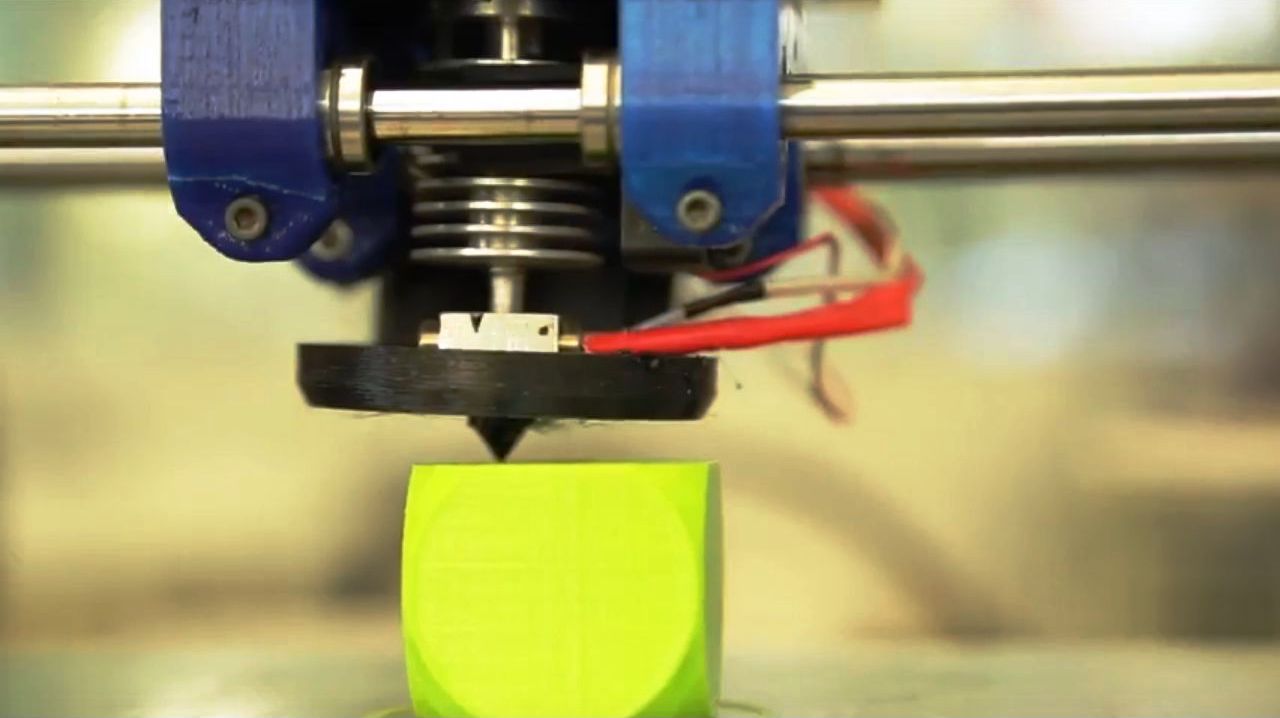

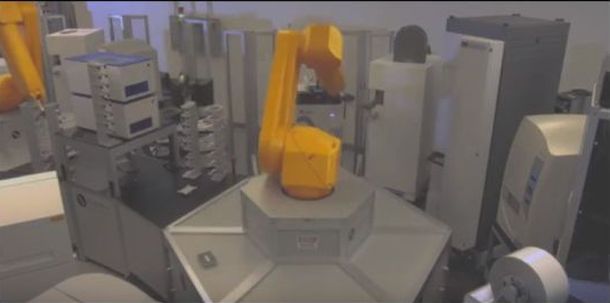

Plant operators are responsible for monitoring all stages of the production process. Their usual tasks include those of the operation and control of the devices, equipment or facilities for the various industrial processes and product manufacturing phases, in accordance with the specifications established in the relevant technical documents and respecting the safety, product quality and process efficiency standards, also being responsible for the basic maintenance of the work area equipment. They are integrated into a work team that depends on an intermediate command (manager or plant technician) and interact with professionals of equipment maintenance and quality control and with the workers who supply raw materials.

Tasks

- Prepare and condition plant machines, equipment and facilities.

Prepare process machines that need to be repaired or reconditioned, and prepare them to be connected or integrated into the process.

Prepare a section, process area or plant for reparation or reconditioning, and get it ready for operation in line with the established procedures.

Provide the thermal conditions, obtain steam and purified water and provide oxygen or other gases in the processes in the conditions required. - Perform industrial process operations.

Keep the machines and area for which they are responsible clean and in suitable condition.

Perform basic maintenance operations on machines and fill in incident forms.

Distribute materials in the process in the conditions required, through solid and/or liquid transportation.

Undertake or take part in the start-up and stoppage of processes, whether continuous or non-continuous, synchronising operations where necessary.

Pack industrial products using the packaging material described and accepted by the quality assurance programme, in conjunction with the plant labourers. - Perform local control in the plant.

Oversee the supply and replenishment of auxiliary products and materials.

Use local control instruments to achieve and maintain the operational system.

Measure the process variables with the tools and frequency established.

Regulate and control the established manufacturing processes, whether using control centres or manually and following the production plan, making any necessary adjustments.

Take samples of the product during the process, in order to support the quality control operations, to obtain products of the quality required.

Carry out periodic quality control tests on the product and process.

Record the measurement and control results in line with established procedures, timeframes and sequences. - In chemical and similar companies, it prepares and tests raw materials.

Receive and store chemical raw materials and packaging material in the specified conditions and with the security required.

Take samples for quality assurance, in the conditions specified and using suitable instruments.

Perform simple tests within the established time frame and using the specified methods and safety conditions.

Record the results and notify any incidents that occur. - Comply with good manufacturing practices and safety and environmental standards.

Comply with internal safety and environmental standards when operating machines in all facilities and areas.

Prevent personal risks through the use of protective equipment.

React quickly and appropriately to emergencies.

Effectively coordinate with shift handover staff and with other departments.

Actively participate in exercises, drills and emergency scenarios in line with the established procedures and plans. It is responsible for keeping these files of workers updated and expanding them.

| Catalan | Beginner

| Catalan | Beginner | English | Advanced

| English | Advanced

Open

Open

| Catalan | Advanced

| Catalan | Advanced