Manufacturing specialist

Other denominations

Production Controller, Team Leader, Line Driver or Production Supervisor.

Description

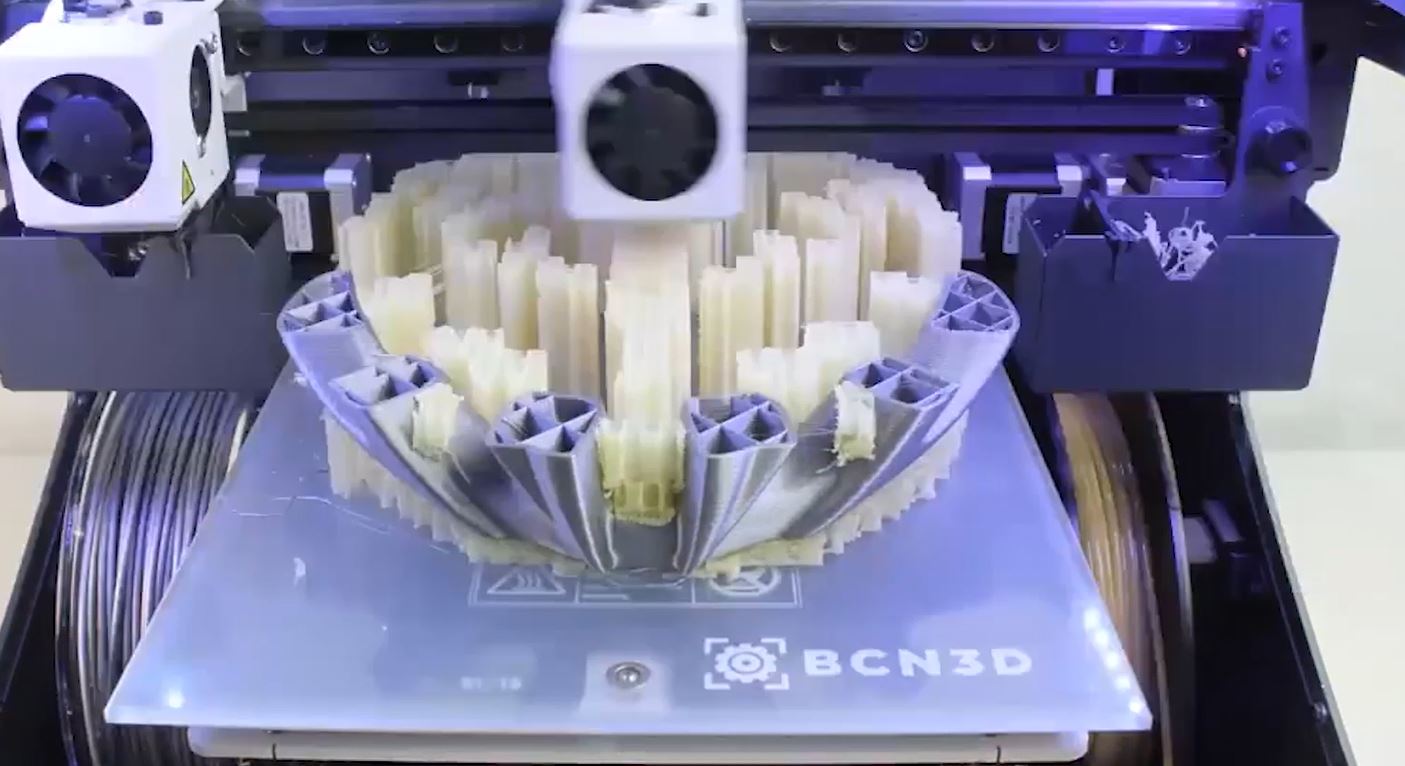

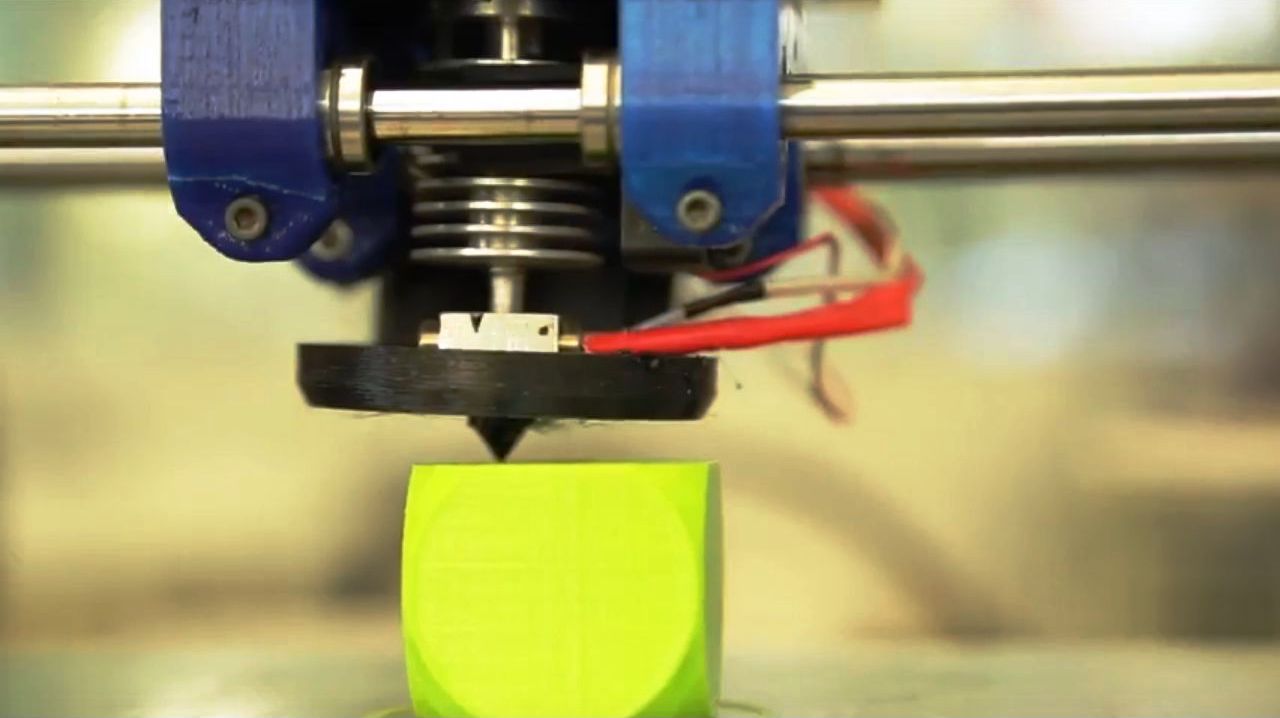

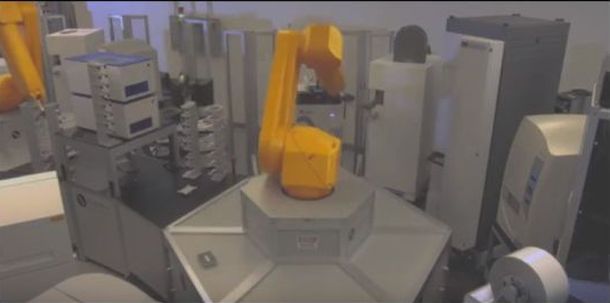

Recently, according to the increasing quality industry requirements, a complete automation of manufacturing processes has begun, which has forced workers to adapt to new technologies. This has led to a greater responsibility on the part of the manufacturing operators and a rising importance of the intermediate workers to control different process operations. Notable among these is the manufacturing specialist, who directly supervises manufacturing and distribution tasks associated with a particular shift time, production line or product. It includes operation, cleaning, start-up and shutdown equipment and work team organization, which involves informing the production manager when any anomaly appears.

This professional, who works at large and medium-sized companies, is also responsible for the orders preparation in the warehouse and the compliance with internal rules and procedures concerning quality, safety and environment by operators and workers in charge. Finally, manufacturing specialists must guarantee that the obtained product meets the required selling conditions.

Tasks

- Organizes and manages the operation of a production line or equipment.

It is responsible for organizing the warehouse based on the identification, reception and dispatch of raw materials, according to transport availability and distribution.

Oversee stocks of raw materials, tracking order proposals, ensuring that all materials are available when needed.

It controls raw materials weighing, labelling, transfer and storage, to be used in production.

It organizes roadmap defined work for manufacturing process, drawn up by the production manager in a particular area, plans equipment and materials use and distributes workers and laborers manufacturing tasks.

Controls elaborate materials transport from one phase to the next one, as well as work areas order and cleaning.

Determines maintenance plans for the machinery used based on process sequences.

Writes and designs work procedures, protocols, record sheets and other manufacturing, packaging, and labelling documentation with the help of senior technicians. - Controls manufacturing facilities, keeps equipment and ancillary services ready for the industrial process, and executes manufacturing orders.

Produces the supervision sheet for production teams to determine their maintenance needs.

It oversees the manufacturing operations and equipment use, thus verifying the raw materials introduced in the process and the finished products.

It produces sheets that evaluate the severity of the anomalies detected in the equipment and the facilities.

It proposes ideas for continuous improvement of the processes and organization of the production and auxiliary facilities, so that it is responsible for the productivity of its work line.

Signs the work permits required to carry out equipment and facilities maintenance operations. - Oversees compliance with quality parameters, safety, hygiene and environmental standards in operations locally controlled.

Assign to each task the established registration forms.

Identify quality inspection points at the production line.

Evaluates warehouse security measures and their signalling according to the regulations.

Check first aid condition and emergency instructions material.

Evaluates working areas based on safety regulations and reports.

| Catalan | Beginner

| Catalan | Beginner | English | Advanced

| English | Advanced

Open

Open

| Catalan | Advanced

| Catalan | Advanced