3D printing specialist

Description

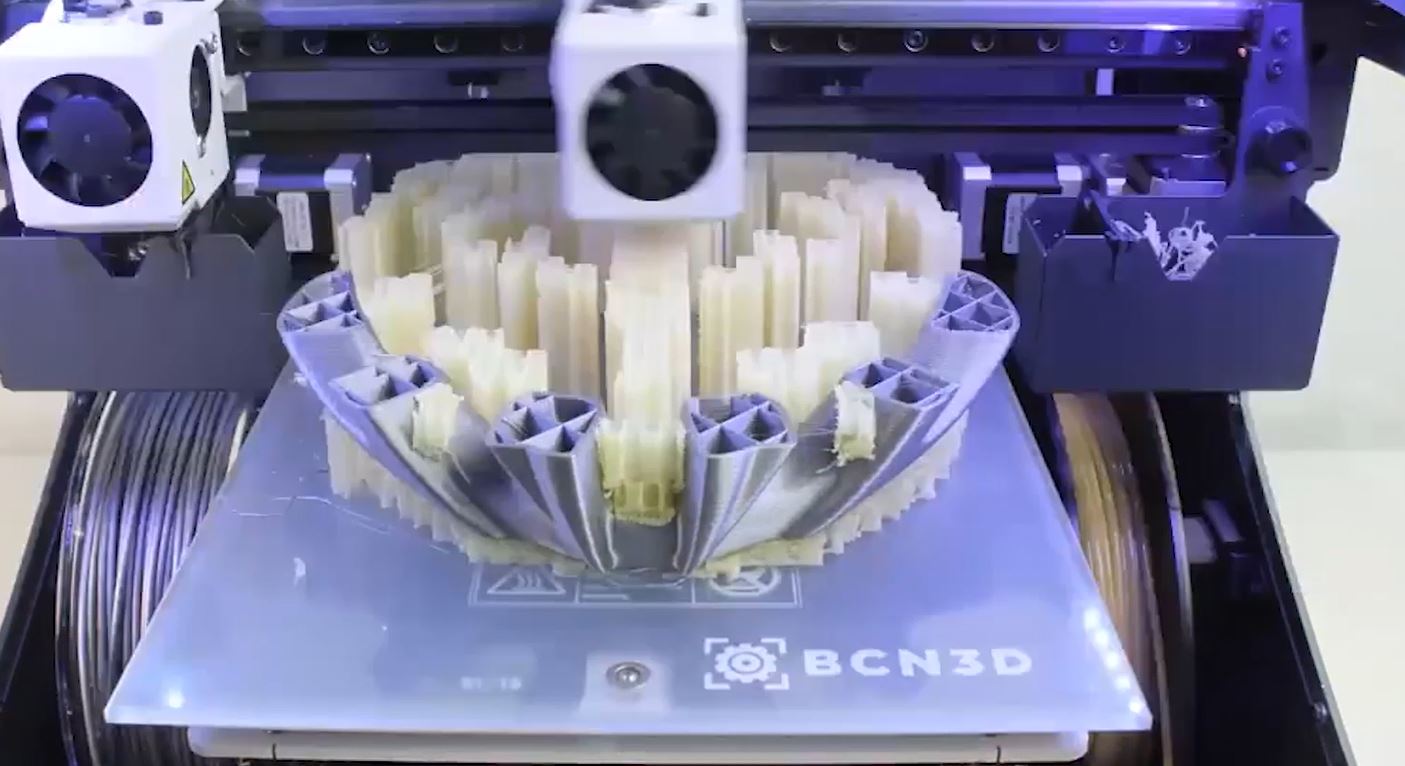

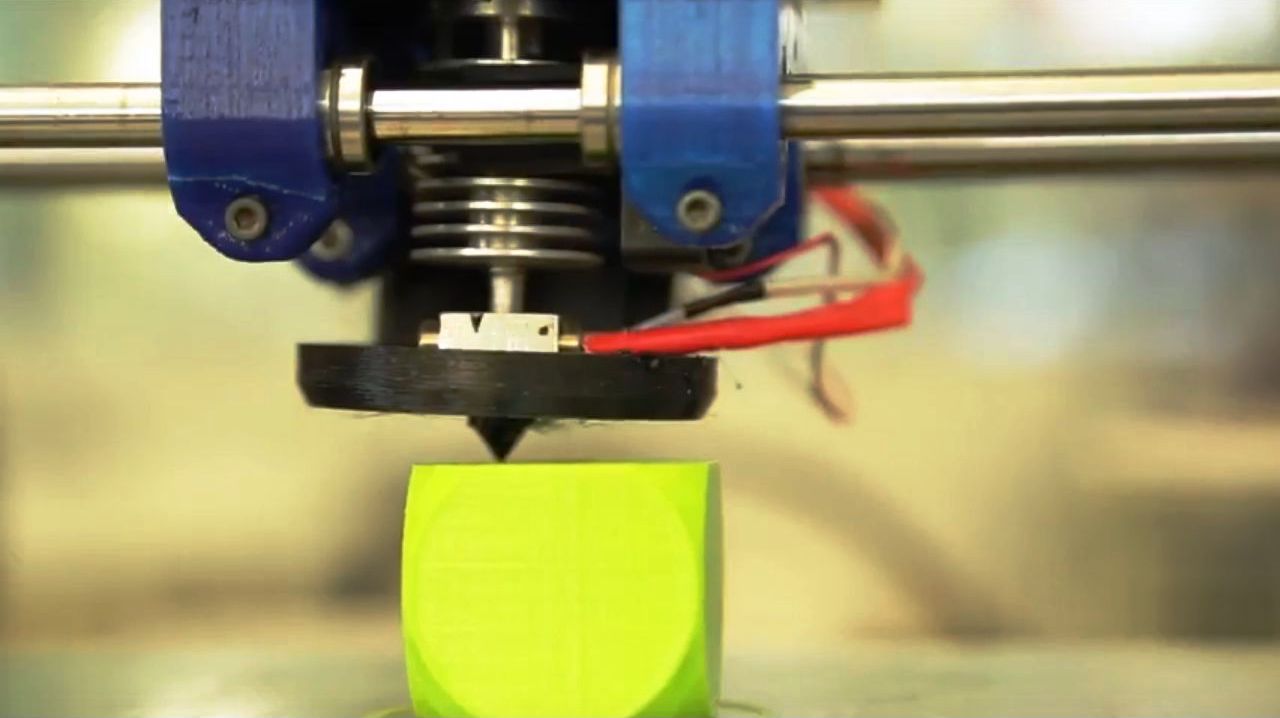

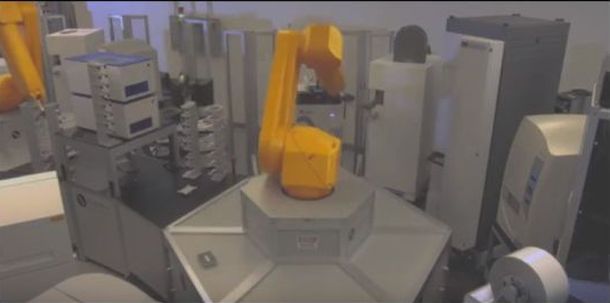

The job of 3D printing technicians is to produce physical 3D representations of computer-generated models. 3D printing, named after the three dimensions of every object: height, width and depth, responds to the need to create prototypes more quickly and economically than is possible with computer-aided design, based on design files (CAD, which stands for Computer Assisted Design).

3D printing technicians work with industrial companies or services bureaux in the modelling and prototyping sector. The increasing application of 3D printing in the prototyping and production processes of industrial companies has given rise to several 3D printing companies offering their services and know-how.

These professionals mainly use the additive manufacturing technique, which involves the 3D printer depositing material in a series of very thin, successive layers to create an object from a digital format. The main advantage of this printing over other manufacturing methods is that it eliminates design restrictions, such as the possibility of demoulding in parts manufactured by injection moulding and facilitates the printing of more complex parts where assembly is often eliminated, making it possible to generate a mobile part and eliminating the process of assembling the parts that would form this assembly with traditional manufacturing.

Initially, 3D printing technology was used for the manufacture of prototypes and models for sectors such as architecture and industrial design, but thanks to the reduction of costs and the increase in available materials and technologies, 3D printing is increasing its presence not only in the industrial field, but also in the domestic, advertising, artistic, training and in the generation of human tissues. Currently, 3D printers can print in any material, thus expanding their potential as a manufacturing resource. Thus, materials used for printing include nylon and other plastics, stainless steel (mainly in powder form for compaction technologies) and other metals such as titanium, silver and gold. Paper and food (mainly chocolate, sugar or meat) are also used. And it is applied in the following industrial fields: automotive, food, medicine, arms, aviation and aerospace, jewellery, architecture and fashion.

Tasks

- Create and manage digital assets and optimise, refine and correct model geometry.

- Evaluate customer designs to ensure they are compatible with 3D printing.

- Collaborate with the technician specialising in specialised software (generally CAD software tools that allow parts to be designed, studies and optimised according to their purpose and application), devoting special importance at this stage to taking advantage of the possibilities of additive manufacturing (which allows shapes and geometries that are beyond the possibilities of conventional manufacturing equipment widely used in industry). The aim is to optimise geometrically the products of additive manufacturing.

- Work with the product management team on product development, including the establishment of design processes.

- Detect the needs and opportunities for the use of additive manufacturing in the production processes of the company or project in which these professionals work, assessing the economic costs and business opportunities of using 3D printing.

- Know the advantages and limitations of each type of printing technology to be able to suggest which type of printing is most suitable for each specific application that arises (finishing of parts, mechanical properties or dimensional tolerances required, printing time and cost of producing each part according to the different technologies).

- Implement additive manufacturing processes as a means of manufacturing products (machined parts, short series production of spare parts, or any type of organic or mechanical object in metal or plastic, for example), which may entail, within the company where the 3D printing process is implemented, the reorganisation of internal production processes, both in the field of production itself and in the supply of materials (logistics).

- Evaluate alternatives to rationalise the printing process, carrying out finishing tasks on the printer, such as sandblasting or polishing, and collaborate with production staff to initiate new work processes.

- Plan and manage the daily schedules of the 3D printers, for optimal coordination of the production process.

- Monitor stock levels of material and consumables, ordering material so that purchase orders are generated when necessary.

- Help to maintain the general production environment, such as cleaning or repairing the 3D printers and all the equipment around them (nitrogen lung, air compressor, sorting machine, UV oven, etc.), managing repairs that require the intervention of the external maintenance service. Sometimes machines must be sent to the Technical Assistance Service or a technician has to come. It is important to follow up and understand what the problem was, in order to avoid it in the future and, if it happens again, try to make the repair in-house.

- Know the requirements of the main additive manufacturing and 3D printing technologies on the market, as well as their comparative advantages and disadvantages.

- Keep up to date with the latest developments in 3D design, capture and modelling tools and technologies.

| Catalan | Beginner

| Catalan | Beginner | English | Advanced

| English | Advanced

Open

Open

| Catalan | Advanced

| Catalan | Advanced