Industrial Chemicals Plant Assistant

Other denominations

Chemicals Plant Assistant; Chemical Processes Assistant

Description

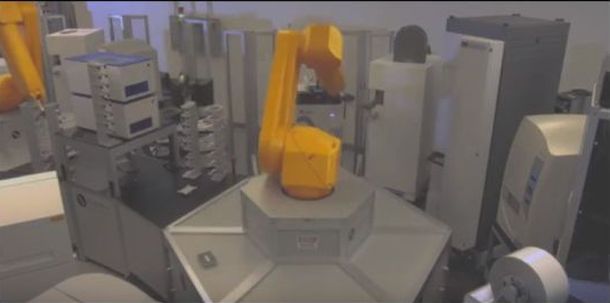

The industrial chemicals plant assistant helps carry out basic and control operations of the various chemical processes, controlling the operation, start-up and stoppage of the machines, equipment and installations comprised in them. They are also responsible for maintaining the established safety, quality and environmental conditions and for the basic maintenance of the equipment in the work area.

Work is undertaken in large-, small- or medium-sized companies working in the fields of basic chemicals (oil refining, petrochemicals, inorganic chemicals, organic chemicals, fertilisers, plastic raw materials, synthetic rubber, pigments and synthetic fibres) or chemicals processing (paints, varnishes, lacquers, adhesives, printing inks, sensitive photographic material, essential oils and aromatic substances, glues and gelatines for the textile and leather industry, soaps, detergents, bleaches, explosives, wax and paraffins). Also in other sectors where there are facilities where basic chemicals or energy production operations are carried out or auxiliary operations such as waste treatment, water treatment and purifying plants.

Tasks

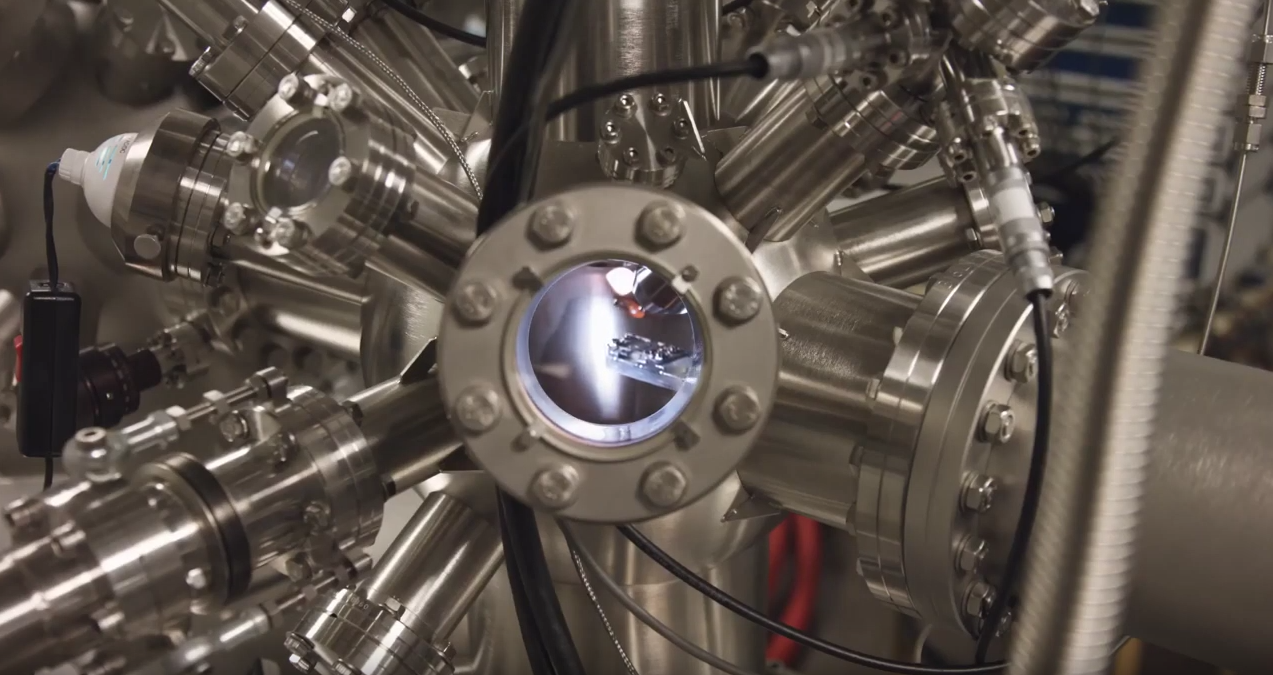

- Prepare, start up, control, adjust and stop the machines and installations under their responsibility.

Prepare the machines and equipment for the process.

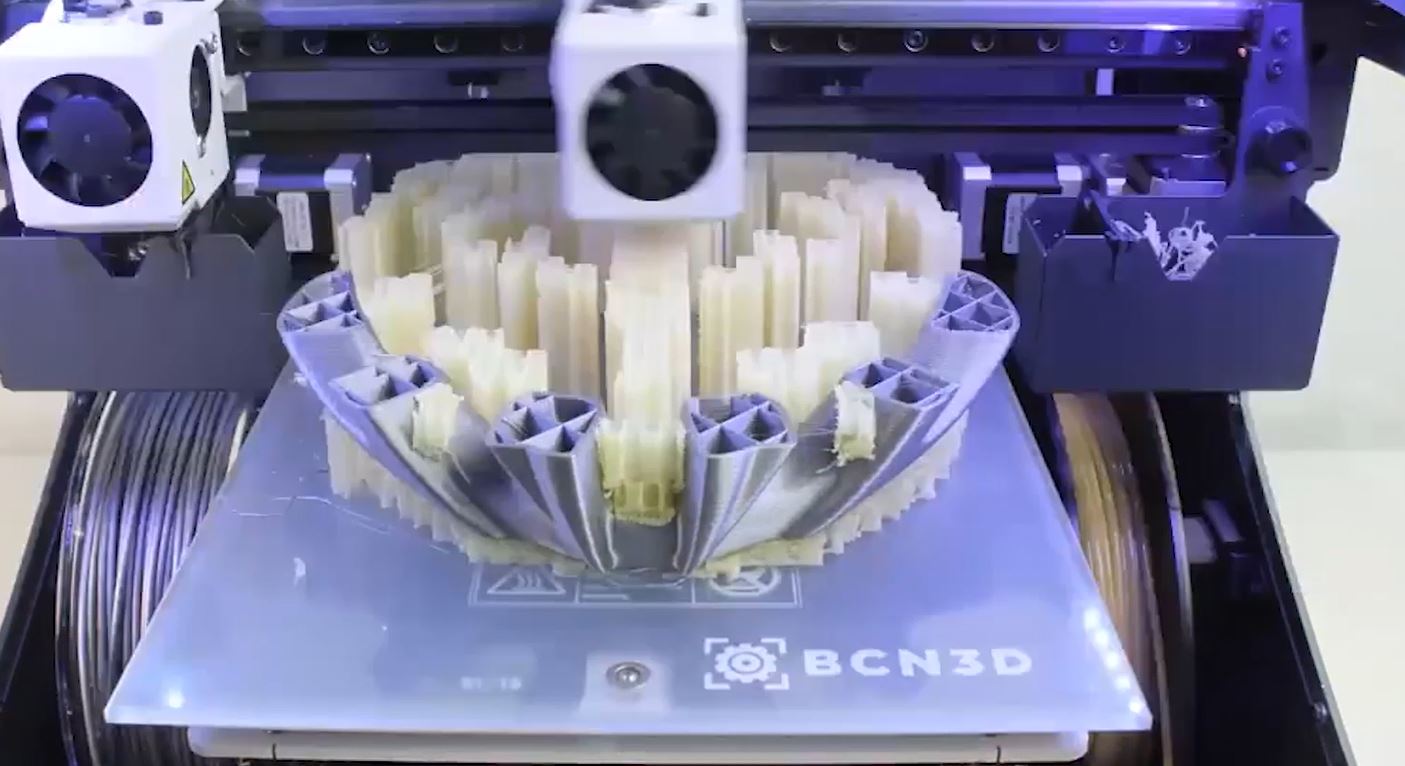

Carry out the operations to turn machines and equipment on and off, following the established procedures or instructions received, collaborating in achieving the total operation with the other operations. - Monitor gauges, calibrators and electronic instruments on one or more machines for the manufacture or formulation of chemical products

Know and control blenders, heaters, extruders, dryers, presses, encapsulators, granulators or coating machines.

Measure, weigh and load chemical ingredients following the formulation notes.

Make the necessary calculations to get the mix or solution to obtain the planned formula.

Select separation systems according to the separation to be done and the rules set down and start or stop them according to the correct sequences. - Take samples and conduct routine chemical and physical analyses of products and record production data.

Take samples according to the established procedures at the right time and under the required conditions.

Correctly identify the sample.

Obtain the measurements and results with the necessary precision. - Clean and carry out minor operations on machines and installations.

Carry out simple maintenance operations assigned, such as the regular cleaning of filters, change of blanking discs, adjusting seals and closures, whenever required.

Keep the equipment and elements in the assigned area in ideal operating conditions through operations scheduled in the maintenance charts or programmes, such as greasing equipment in maintenance, checking instruments for the simple analyses to be conducted, collaboration in maintenance operations of fire prevention and personal protection equipment.

Apply the procedures for carrying out the simple maintenance work assigned to the work place and to the handling of the tools required with precision.

| Catalan | Beginner

| Catalan | Beginner | English | Advanced

| English | Advanced

Open

Open

| Catalan | Advanced

| Catalan | Advanced