PLC programmer

Description

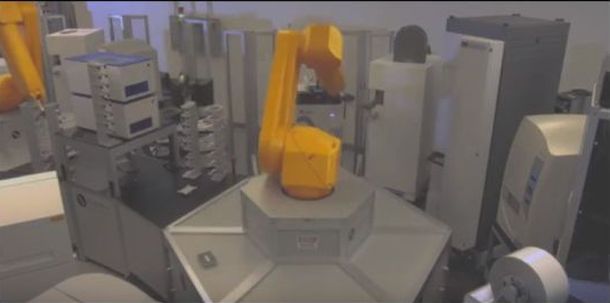

PLC programmers are the professionals involved in industrial automation using programmable logic controllers. The PLC (Programmable Logic Controller) is found throughout today's process and manufacturing industries. Initially, it was built to replace electromechanical relay systems to provide a simpler solution for modifying the operation of a control system.

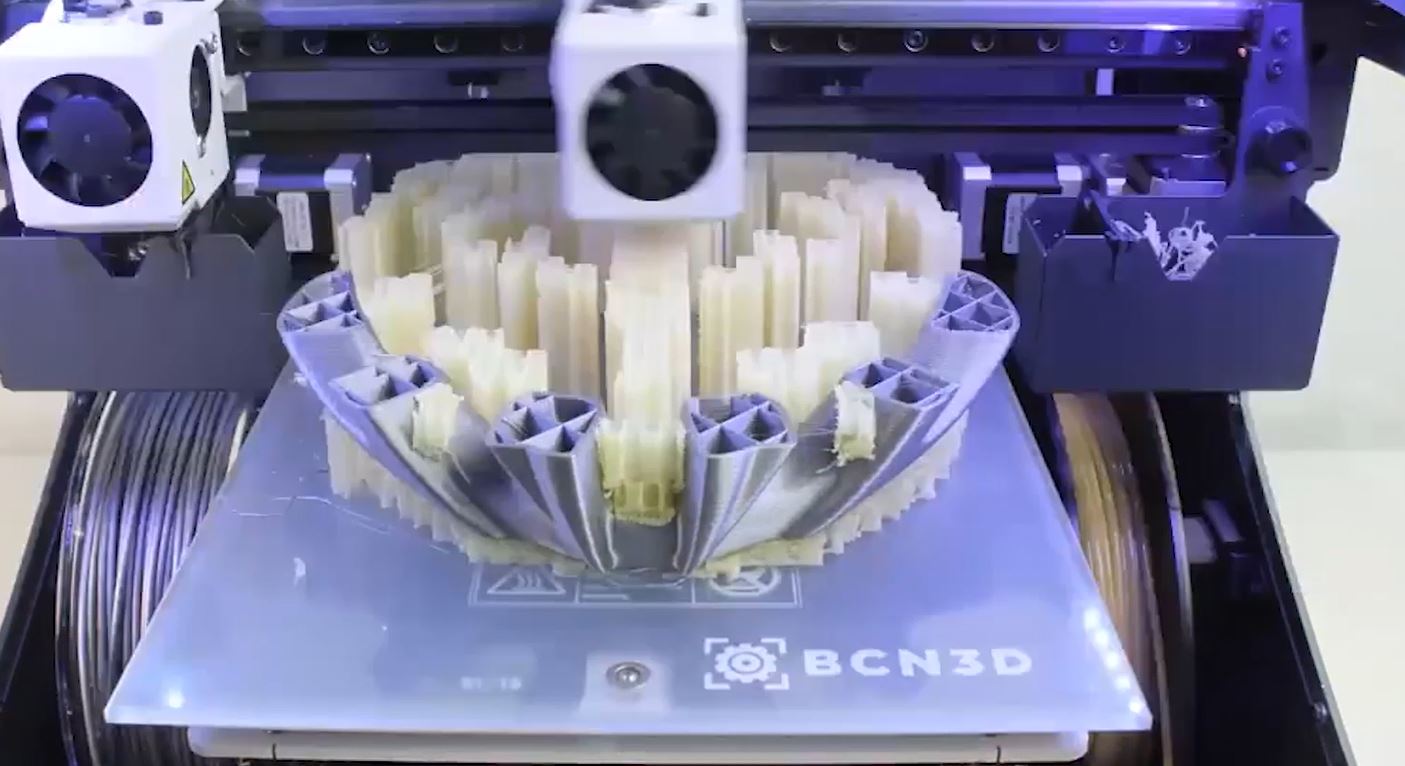

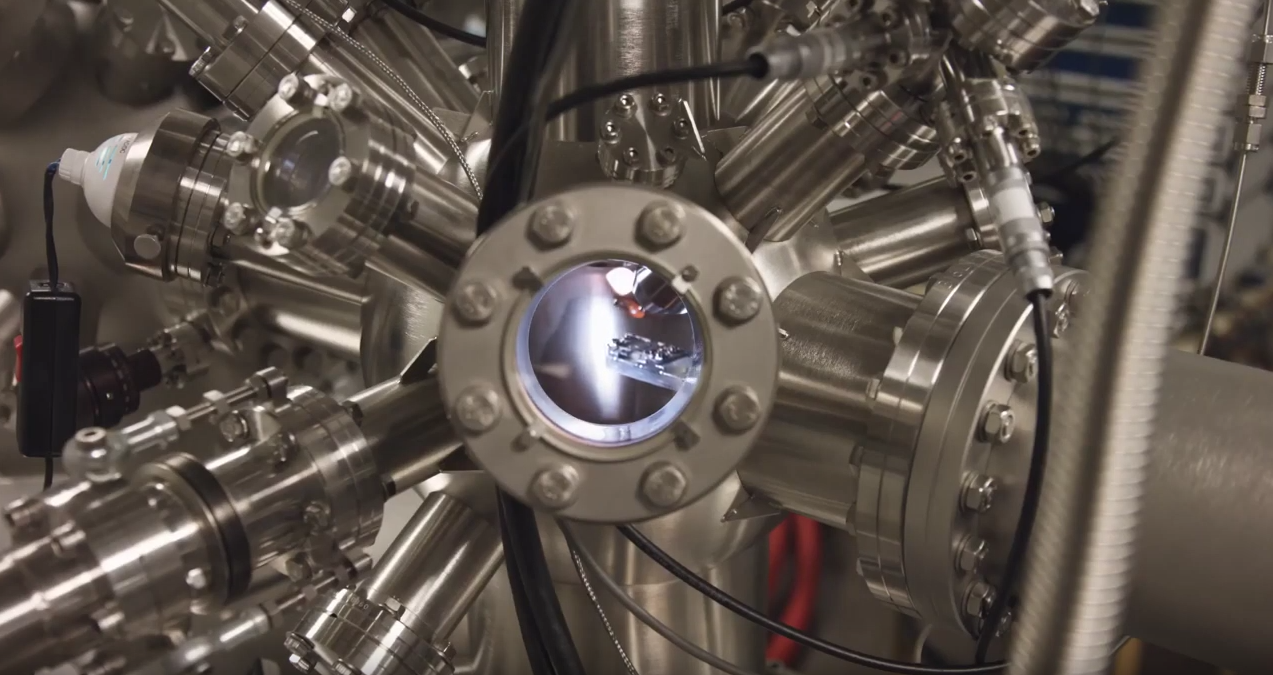

A PLC is a computer used for industrial automation, which controls the production process. PLCs can automate a specific process, a machine function or even an entire production line. The PLC receives information from connected sensors or input devices, processes the data and activates outputs based on programmed parameters. Depending on the inputs and outputs, a PLC can monitor and record run-time data such as machine productivity or operating temperature, automatically start and stop processes, generate alarms if a machine is not working properly, etc.

PLC are applied to industrial production processes in a variety of sectors, such as:

Food: packaging, bottling, storage, etc.

Paper mills and sawmills: sawmills, chipboard and laminate production, etc.

Machine tools: lathes, milling machines, drilling machines, etc.

Metallurgy: furnace control, rolling mills, foundry, welding, forging, cranes, etc.

Automotive: assembly lines, welding, paint booths, etc.

Chemical and petrochemical plants: oil pipelines, refining, etc.

Energy production: power plants, turbines, solar energy, etc.

PLC programmers are responsible for the commissioning, optimisation and changes of the operating and maintenance parameters of the machines used. The machinery featuring these controllers is used in production processes, where these programmers develop and optimise them to automate the electro-hydraulic, electro-pneumatic and electro-mechanical processes that take place in the industrial production plants of companies.

Tasks

- They are in charge of programming machinery for industrial automation, collaborating in the programming, design and development of software for industrial environments, based on different standards and according to the demands of the clientele, adapting automated production lines for different economic sectors.

- Design, develop and optimise control programs (PLCs) and perform the regulation of the machinery considered relevant.

- Define control systems, carry out programming and supervise the start-up of machinery for the execution of protocols.

- Correct programming errors, in the configuration of data display screens and detect possible electrical problems or in the design of the installations and are in charge of their subsequent resolution.

- Prepare electrical diagrams and define control and communication architectures.

- Configure, programme and integrate communication systems.

- Provide proposals to solve the problems or incidents detected and write reports on the status of the projects following the company's protocols.

- Carry out PLC preventive maintenance.

- Manage schedules and resources.

- Make modifications to production lines.

- Support new installation and automation projects.

| Catalan | Beginner

| Catalan | Beginner | English | Advanced

| English | Advanced

Open

Open

| Catalan | Advanced

| Catalan | Advanced