Quality Control Technician

Other denominations

Quality controller; Quality analyst; Quality control analyst

Description

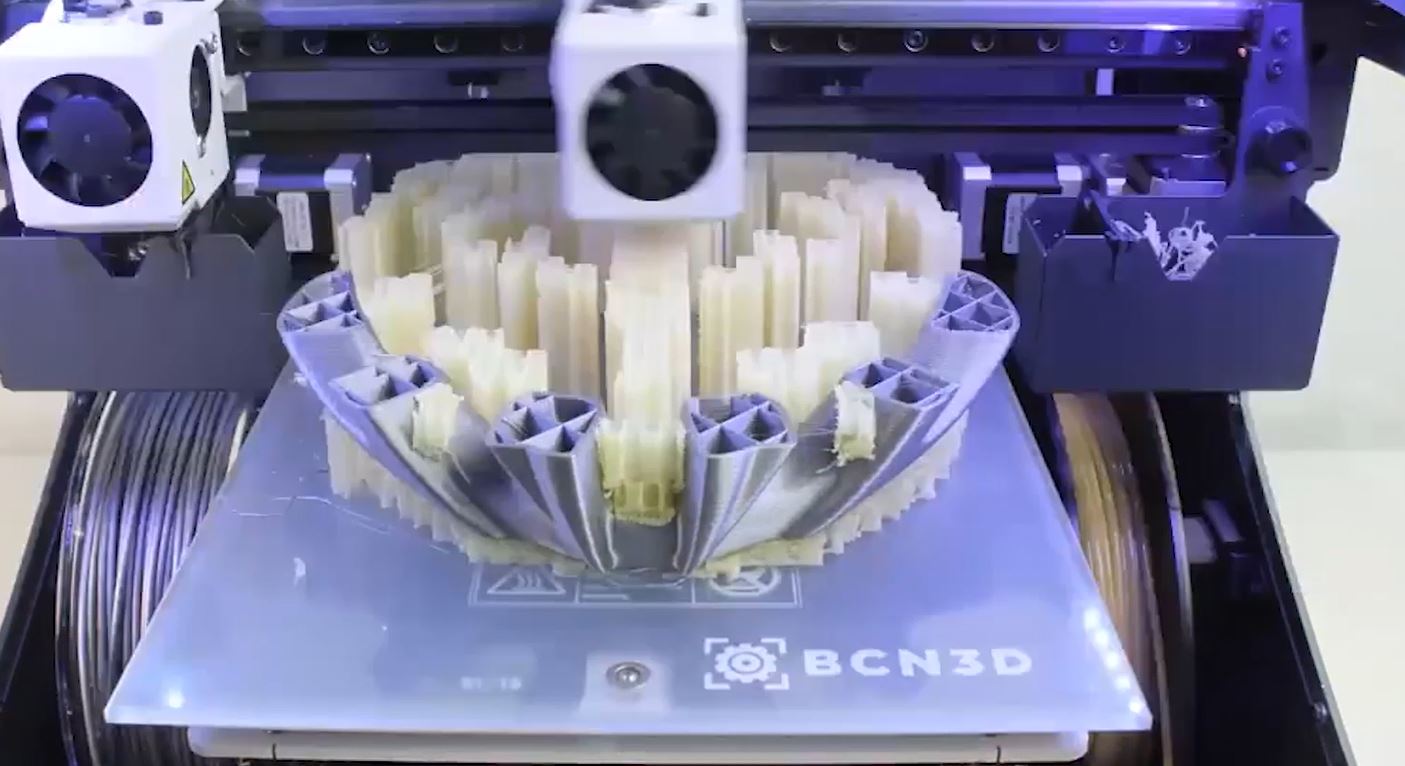

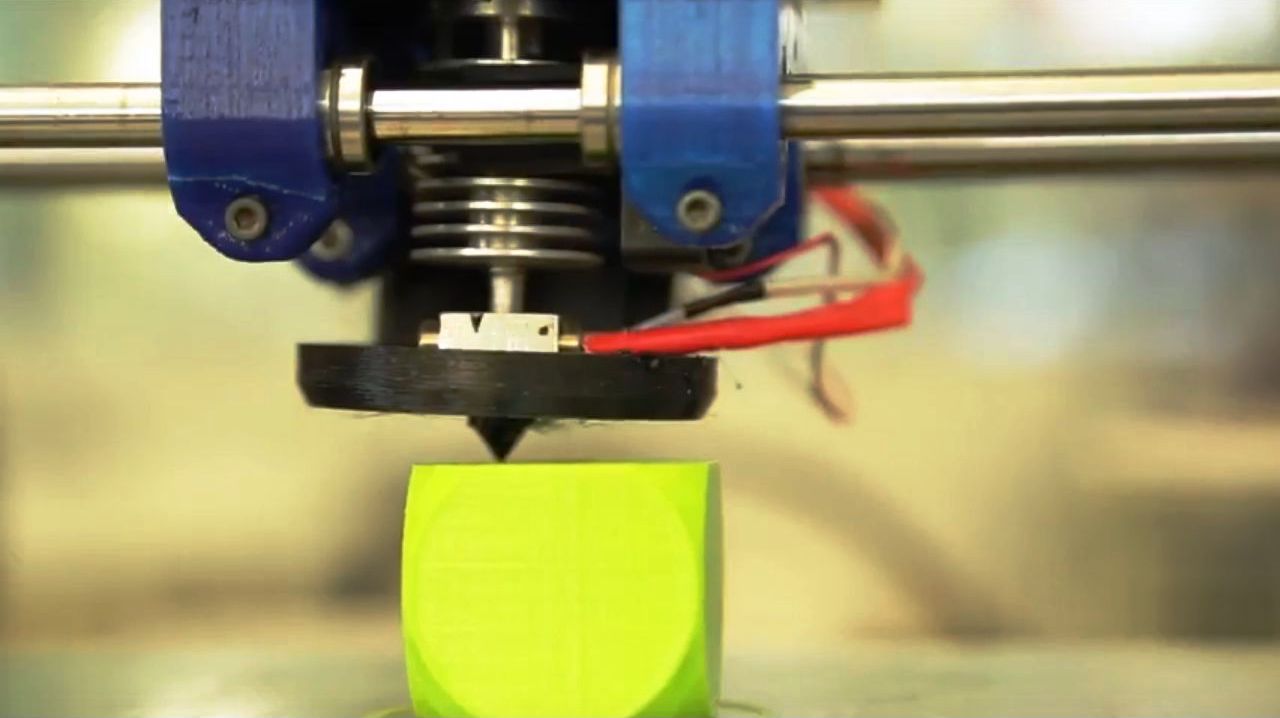

Quality has become a crucial factor in determining companies' competitiveness, building up trust among customers and consumers with regards to the product supplied and ensuring a heightened degree of efficiency in processes. The aim of quality control is to meet the quality targets required for the different operations. It covers the whole of the production process, from raw materials to final products, including all of the possible intermediate stages. The role of the quality control technician has emerged as a progression of the figure of the laboratory analyst, and forms part of production support teams or companies' quality departments. Their responsibilities include taking statistic samples of raw materials and intermediate and finished products, carrying out routine and non-routine tests using set methods, calibrating and performing maintenance on equipment, managing the documentation related to trials and samples, ensuring compliance with specifications, reviewing possible deviations, and drawing up technical documentation. These technicians may specialise in a particular area of the quality control process (raw materials, process control, inventories, product assessment, R&D, etc.), and may, as they gain more experience, move up in the company, becoming shift quality managers, laboratory supervisors or quality assurance technicians.

Tasks

- Carry out preparatory tasks prior to performing control trials on raw materials and products.

Be familiar with the daily work orders in order to know which products to control.

Take and identify representative samples according to established procedures and statistical parameters.

Perform the separation of gas, liquid and solid mixtures using the most suitable technique.

Perform maintenance on, calibrate and control the laboratory instruments and equipment.

Clean and repair the equipment and machinery used in the trials. - Responsible for performing routine and non-routine tests on raw materials and products throughout all of the stages of the production chain, using validated methodologies.

Interpret test procedures, media, products and reagents to be utilised and the data to be obtained.

Perform physical and physicochemical tests to analyse the properties of materials and identify substances, including measuring viscosity and humidity.

Perform qualitative and quantitative chemical tests to identify and measure chemical substances, using simple instrumental techniques.

Identify and count existing microorganisms through microbiological testing.

Analyse water samples to ensure the quality of the water being used in the production process, according to the established working procedure.

Perform stability testing on products.

Review and update operational procedures, sometimes helping to resolve analytical or instrumental problems. - Establish whether or not the raw, intermediate and packaging materials comply with the quality control specifications.

Review the data obtained and prepare validation or deviation reports with regards to specification compliance, analysing non conformities.

Prepare analysis certificates and ensure that batch records have been revised prior to being approved by the laboratory or department manager.

Recommend modifications to the existing standard quality or production parameters in order to maximise the quality within the capacity. - Record data from and draw up technical reports on the basis of the tests performed, communicating the results to the manager.

Input data and control documents, applying statistic quality control procedures.

Maintain quality control records for the tests, reagents, suppliers and equipment, according to the regulations.

Help to draw up quality control-related standard operating procedures (SOP). - At all times act according to the established health and safety, quality and environmental standards, ensuring compliance therewith.

Operate all of the equipment used in the quality control process, according to the SOP specifications.

Provide quality control-related technical support to the production and R&D departments.

| Catalan | Beginner

| Catalan | Beginner | English | Advanced

| English | Advanced

Open

Open

| Catalan | Advanced

| Catalan | Advanced