We use our own and third-party cookies to improve your browsing experience and to offer you content and services of interest.

Continued browsing on your part shall imply full acceptance of our cookies policy.

Your consent preferences

The following panel allows you to customize your consent preferences for any tracking technology used to help us achieve the features and activities described below. For more information on how these trackers help us and how they work, please see the cookie policy. You can review and change your choices at any time.

We use our own and third-party cookies to improve your browsing experience and to offer you content and services of interest.

Continued browsing on your part shall imply full acceptance of our cookies policy.

Technical office manager

Description

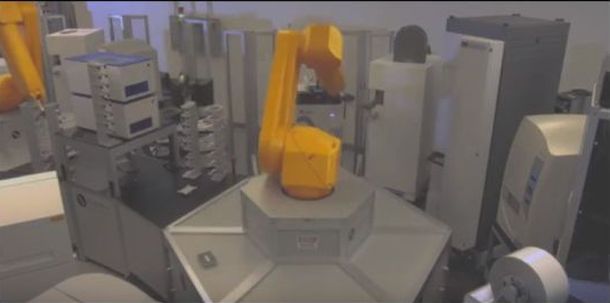

In the production process, the person responsible for the technical office is the professional who applies flexible production systems and product quality verification techniques. The objective of this position is to optimise the production process. Use SMED techniques (Single Minute Exchange of Die) of rapid utensil changes, in relation to flexible production systems. The application of these techniques is designed to reduce the preparation time of machines and tools, including from the manufacture of the last valid piece of a series up one until the acquisition of the first correct piece of the next series. In terms of quality verification, Poka-Yoke techniques are used that allow the prevention of human errors, and to detect and delete flawed pieces in an intermediate point of the production phase. Production costs are reduced with these techniques, given that they allow for the detection and subsequent deletion of flawed pieces in an intermediate point of the production phase. In this way, faulty parts are eliminated from the production process, which ensures the quality of pieces and has an impact on consumer satisfaction, and minimises the expenses of the process. In the aeronautic sector, the reduced dimensions of production batches and the complexity of the preparation or parameterisation of machines give vital importance to the optimisation of the preparation process and to this occupation.

Tasks

- Manage staff in the department of technical branch of the company.

- Design manufacturing processes for aeronautical products. In general, production is in small batches that can be repeated a certain number of times over a long time period.

- Manage product quality according to the ISO / 9000 family of regulations.

- Analyse environmental impacts according to the ISO / 14000 regulatory family and other regulations specific to the aeronautical sector.

- Assess and support production areas in the implementation of quality techniques and improvements in production processes.

Training

Regulated training and graduates

No single specialised qualification is required in order to embark on a career in this area. Several different qualifications can prepare you for this position. These include:- Grau: Enginyeria en tecnologies industrials

- Grau: Enginyeria en organització industrial

- Grau: Gestió aeronàutica

Complementary training

Completion of courses in ISO Quality and Poka-Yoke are of great use when embarking on this career. Courses in SMED techniques. Courses in Team and Time Management.Other specific skills

Knowledge of CAD/CAM/CAE tools. An advanced level of technical English is essential.More occupations with this training | Look for more information on the degree of interest

Experience

Soft skills

Gain insight into soft skills | Access the dictionary of soft skills

Interests

Technician

People who show an interest in the technical field find fulfilment in carrying out activities related to the design and manufacture of objects, machines, vehicles and/or infrastructures. These activities require the application of scientific and technical knowledge (laws of physics, calculations and mathematical formulas, properties of the materials, etc). Creativity is also necessary when coming up with optimal solutions for the functional requirements of the products to be designed. Therefore, the pragmatic application of scientific knowledge in order to develop solutions for the benefit of human beings is the main function of occupations in the technical field.

More occupations with your interests | Get to know your professional interests | Glossary of interests

Related occupations

Wage earner

Work hours

Full 8-hour working day.Salary

From 35.217 to 48.123 euros a year gross, depending on experience. Median: 41.168 euros annum gross.

Source: Report "Observatory of Jobs and Salaries of the Labour Market. Barcelona Activa", elaborated by ICSA Grupo. April 2015.Professional category

Middle management

Manufacturing Industry 4.0.

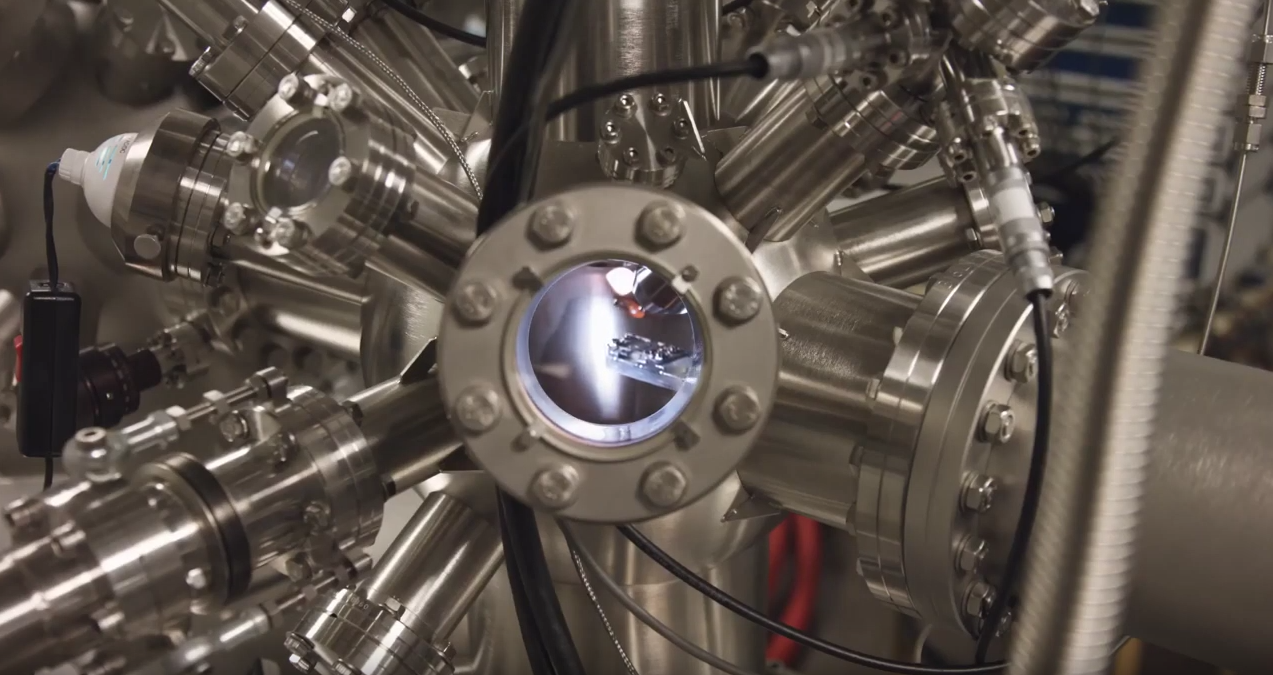

Barcelona is a city with a long industrial tradition, whose businesses have been essential in diversifying its economic activities, generating innovation and added value and creating employment. There is a strong presence of industry-related services in the city and it is home to important hubs for this type of activity, such as logistics, product handling, packaging or industrial product-associated technology. In this context, industry 4.0 seeks to respond to the increased digitalisation of the economy and society and is basically structured around the use of technological advances and the development of communication systems, with a view to sharing real-time information on each of the manufacturing processes employed by companies. Often considered the 'fourth industrial revolution', Industry 4.0 reflects the current transformation of industry, encompassing both large and small firms, to respond to the emerging needs of society using the most recent technological developments.

Metallurgical industry

01-2006 |  | Catalan | Beginner

| Catalan | Beginner

Documents (5 of 8)

Sector Overview: Manufacturing Industry 4.0

04-2024 |  | English | Advanced

| English | Advanced

This document shows data to have more information about the sector that will help you in your decisions regarding your training-work itinerary. This data is grouped into the following

Author: Barcelona Activa

Publishing date: 04-2024

Sector Report: Manufacturing Industry 4.0

12-2023 |  | English | Beginner

| English | Beginner

Sectoral report showing the keys to this economic area as well as the main trends, both consolidated and emerging, in activities and professional profiles and reveals future scenarios.

Author: Barcelona Activa

Publishing date: 12-2023

Focus sectorial: Digital twins

08-2023 |  | English | Advanced

| English | Advanced

A brief report explaining digital twins , their implications in the production process and their impact in the professional profiles.

Author: Barcelona Activa

Publishing date: 08-2023

Compendium of resources for job search in the Manufacturing Industry 4.0

10-2022 |  | English | Beginner

| English | Beginner

Do you know where to find the offers that may interest you according to the sector in which you are looking for work? We put at your disposal the

Author: Barcelona Activa

Publishing date: 10-2022

Conceptual map 4.0 Industry (2020)

01-2021 |  | Catalan | Beginner

| Catalan | Beginner

This conceptual map collects the content that was exposed in the sectorial conference about the 4.0 Industry in 2020. This includes all you need to know about smart factories,

Author: Barcelona Activa

Publishing date: 01-2021

Related Videos (5 of 5)

Sectorial testimony: Inka Guixà

Inka Guixà, general manager of La Farga, tells us which are the most demanded profiles in the Industry 4.0 and manufacturing sector and what skills and knowledge should have the professionals involved in that area.

Sectorial testimony: Joaquim Minguella

Joaquim Minguella, professor of production technologies in the Department of Mechanical Engineering at the UPC, explains which profiles are most in demand in the manufacturing industry and 4.0 sector and what skills and knowledge professionals should have.

Vídeo testimoni Xavier Pi: Indústria 4.0

Xavier Pi, membre de la Comissió Industria 4.0 i codirector del Màster en Indústria 4.0 a la UPC, ens parla sobre el potencial de la indústria 4.0 en el futur de l'ocupació a la ciutat de Barcelona.

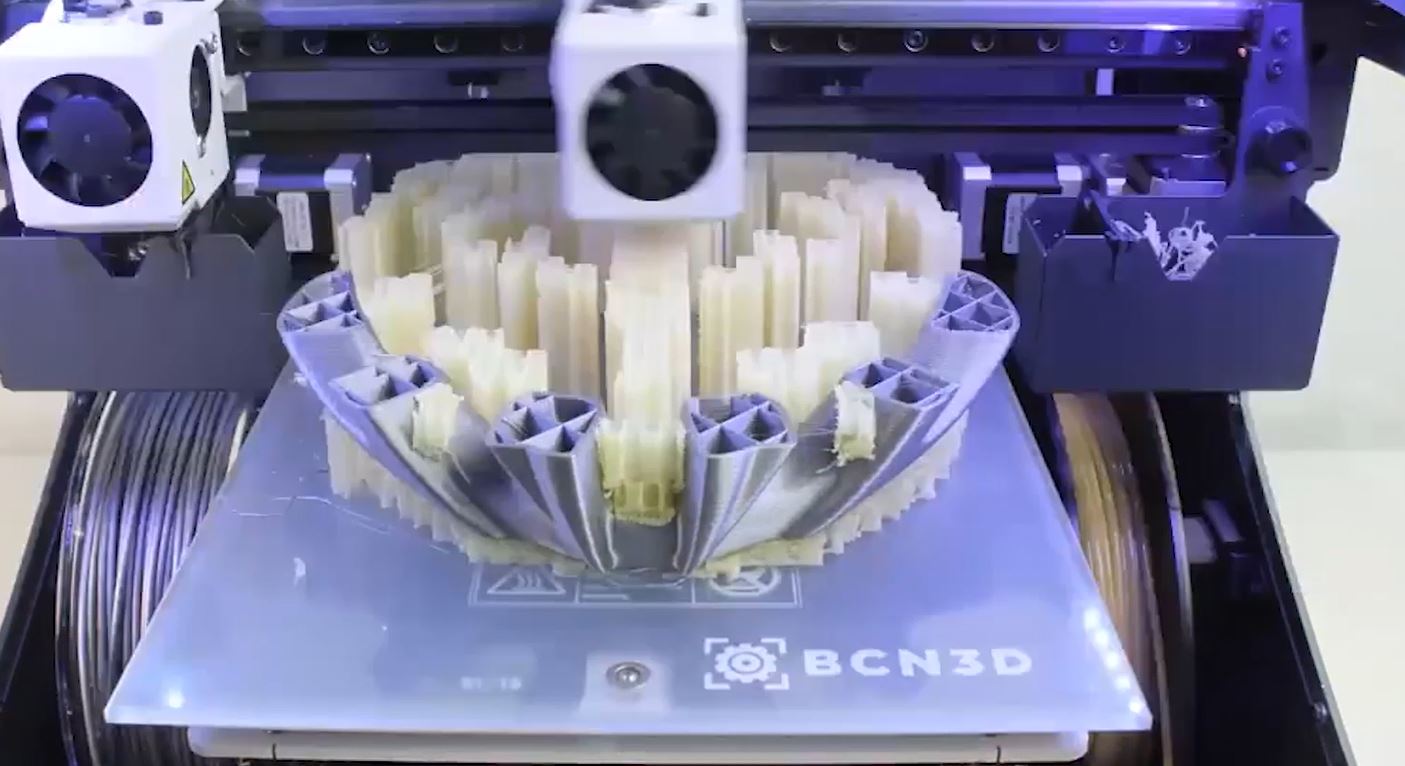

Jornada sectorial: Fabricació Digital i Impressió 3D

Vídeo on trobaràs un resum dels conceptes clau que van debatre els i les professionals i empreses participants a la jornada sectorial sobre l'impacte i potencial de la Fabricació Digital i la Impressió 3D en el futur de l'ocupació.

Jornada sectorial: Indústria 4.0

Vídeo on trobaràs un resum dels conceptes clau que van debatre professionals i empreses participants a la jornada sectorial sobre l'impacte i potencial de la Indústria 4.0 en el futur de l'ocupació.

Useful links (5 of 13)

Manufacturing Industry 4.0.sector Infographic: sector's ecosystem

23-03-2023 |  | English | Beginner

| English | Beginner

Formative centres, reference clusters, guilds, colleges, city projects... All of this and much more in this infographic that will allow you to gain a thorough knowledge of the ecosystem

Author: Barcelona Activa

https://treball.barcelonactiva.cat/infografies/en/ecosistema/manufacturing-industry.html

Manufacturing Industry 4.0 Sector Infographic: Evolution and tech change

15-02-2023 |  | English | Beginner

| English | Beginner

The Manufacturing Industry 4.0 has gone through different transformational processes and milestones in recent decades, which have impacted professionals and asked them for new skills and knowledge. Let us

Author: Barcelona Activa

Date of issue: 17-01-2023

https://treball.barcelonactiva.cat/infografies/en/timeline/manufacturing-industry.html

Manufacturing Industry 4.0 Sector Infographic: From Training to occupation

18-01-2023 |  | English | Beginner

| English | Beginner

In this infographic you will be able to consult which of the formations will allow you to access the Manufacturing Industry 4.0 sector, some of the most outstanding jobs

Author: Barcelona Activa

Date of issue: 05-12-2022

https://treball.barcelonactiva.cat/infografies/en/sector/manufacturing-industry.html

Indicadors laborals Indústria 4.0 - 2021

18-10-2022 |  | Catalan | Advanced

| Catalan | Advanced

Indicadors laborals de la Indústria 4.0

27-04-2021 |  | Catalan | Beginner

| Catalan | Beginner

Pràctica Infografia amb les dades més rellevants de la Indústria 4.0 a l'àmbit Metropolità de Barcelona, 2019. Elaborat pel Departament d'Estudis de la Gerència de Política Econòmica i Desenvolupament

Date of issue: 02-10-2019

Display Industry's jobs:

Manufacturing Industry 4.0.

Production process

- Supply chain

- Milling programmer

- Satellite assembly technician

- Die maker

- Casting specialist

- Metal stamping operator

- Machining centre operator

- Machinery setter

- Turner

- Industrial painting technician

- Welding Technician

- Plant operator

- Industrial Labourer

- Electronics and transmission equipment installer

- Assembler for special technical fabrics

- Welding robot operator

- Electrical, electronic equipment, and electrical machinery fitter

- PLC programmer

- Quality control

- Production line management

- Factory equipment

- Industrial maintenance

- Project and planning

Industrial RDI

- Product development

- Industrial design

- Materials

- Industrial research and innovation

- Research technician

- R&D&I Engineer

- Powder metallurgy specialist

- Specialist in catalysis and catalytic processes

- Laboratory maintenance technician

- Person in charge of the R&D&I technology platform

- Head of technology transfer

- Technology watch manager

- Instrument calibration technician

- Chemical Laboratory Technician

- Intellectual property manager

- Enginyer/a de processos i temps

- Electronic engineer (Automotive industry)

Open

Open