Specialist in catalysis and catalytic processes

Other denominations

Technician responsible for catalytic processes; Specialist in catalytic conversion.

Description

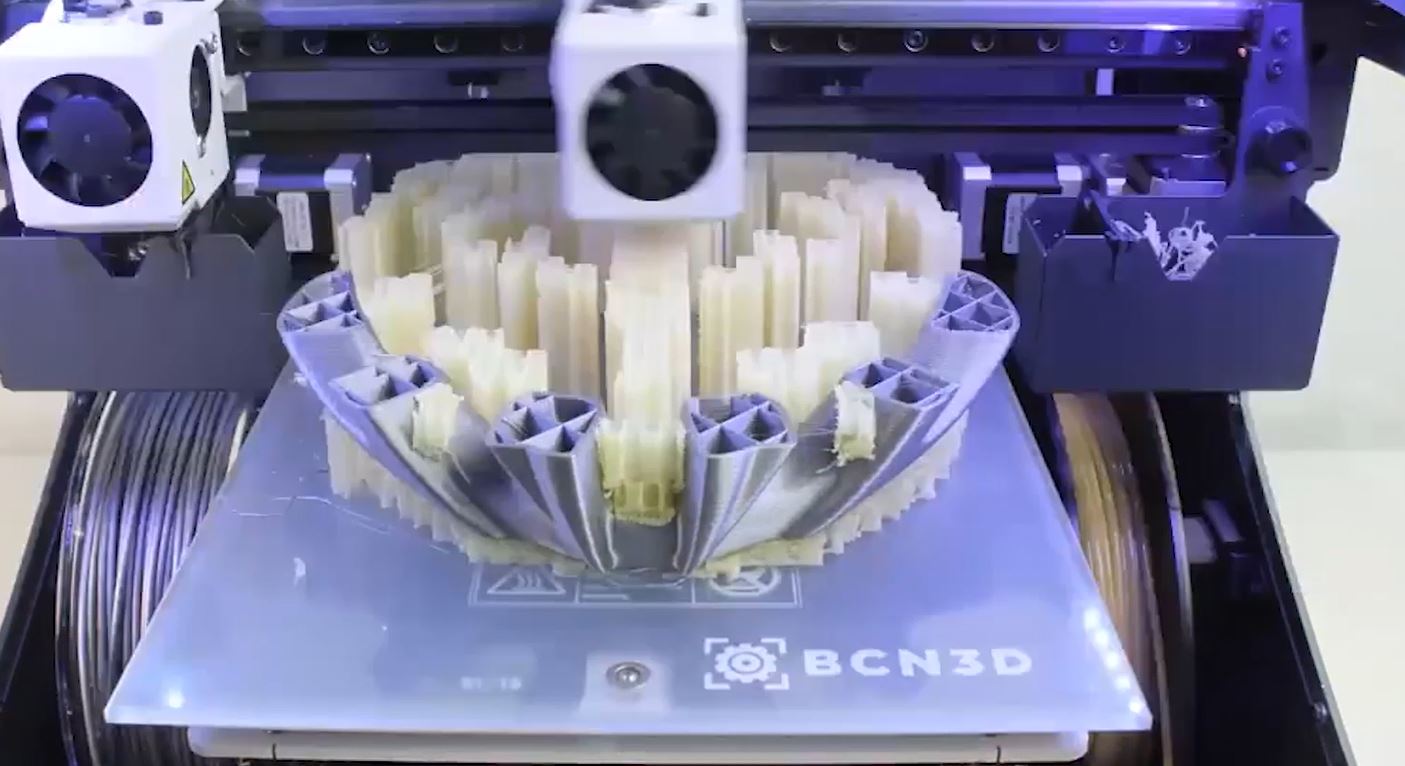

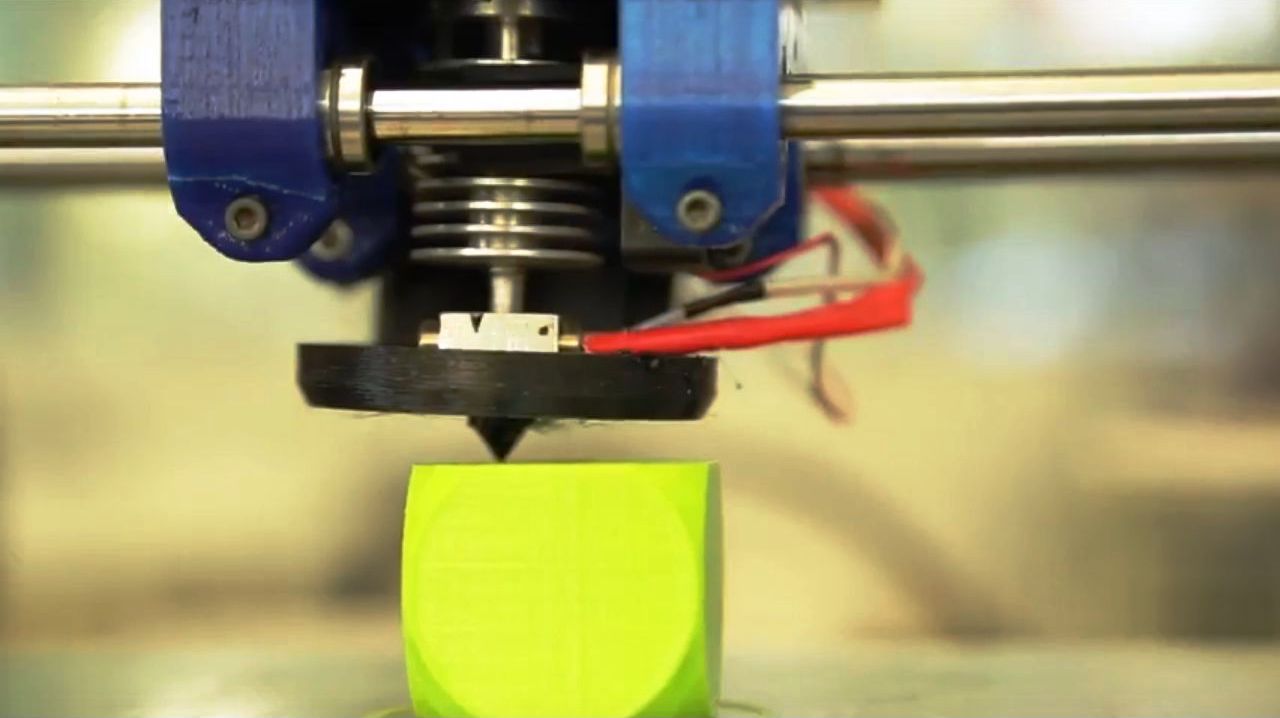

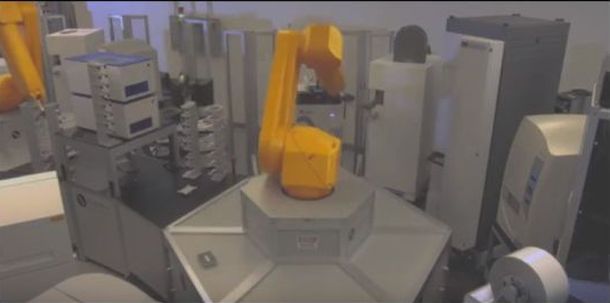

In the process known as catalysis, a small amount of product, called a catalyst, increases the speed of a chemical reaction without being consumed during the process. The catalyst lets the reaction be faster and more selective, so that the chemical process takes place with increased efficiency and less waste production. A new catalytic process requires different phases: the design and synthesis of the required ligands, the preparation and characterisation of the catalysts, activity optimisation and selectivity and scaling at an industrial level. This involves a wide range of professionals specialising in these types of processes, from a purely scientific level to their application at the industrial plant. This occupation centres on the transformation of raw materials in industrial products, primarily in creating organic and inorganic substances. Thus, the person holding this post is in charge of supervising and coordinating the activities of the workers involved in running the equipment, whether this is the preparation of the catalysts themselves, obtaining monomers starting from raw material, in mixing them with the monomer extract to produce polymers or adding chemical additives.

Tasks

- Work in teams to develop new products and improve company processes.

Be part of a multidisciplinary team that focuses on developing catalysts.

Work on developing new useful catalysts for company operations.

Perform research projects and provide technical support on characterising the catalyst.

Plan and execute projects for obtaining new catalysts.

Can discover and develop new analytical methods of catalyst characterisation and the process.

Capable of characterising new commercial catalysts and advising on how to improve them.

Use pilot plant facilities to test and validate new catalysts and develop kinetic models for their industrial scaling.

Select the catalyst according to requirements on temperature and pressure, reagent mass transfer, its weight and size, degradation level and cost. - Coordinate operations, interpret data and seek solutions to problems that arise during the catalytic process.

Know of the theories and how to apply and interpret data from measurement instruments.

Have knowledge of the catalytic processes of different industrial plants and pilot plants.

Correlate data on catalyst characterisation with the quality of the products obtained.

Calculate the amount of product obtained and the performance of the catalyst, using lab reports and computer tools.

Perform controls for the catalytic process in coordination with specialised plant operators, including the temperature, pressure and response time, according to instrument readings, logs and knowledge of process requirements to keep the effeciency of the operation within specific limits.

Supervise the introduction of inert gases in the converters to eliminate explosive steams, purging the catalyst, as well as in reactions with inert atmospheres.

Decide on replacing the catalyst or its regeneration according to established efficacy parameters and quality. - Coordinate laboratory technicians and pilot plant operators.

Take charge of training workers in maching operation and laboratory tasks.

Control the performance of studies in the analysis laboratory and operating protocols.

| Catalan | Beginner

| Catalan | Beginner | English | Advanced

| English | Advanced

Open

Open

| Catalan | Advanced

| Catalan | Advanced