Technician in the manufacture of paper and paper pulp.

Other denominations

Specialized paper industry operator.

Description

Technicians in the manufacture of paper and paper pulp are the professionals responsible for monitoring, steering and overseeing the various manufacturing processes, tailoring them to the needs of the company according to established quality, safety and environmental standards. Paper pulp is obtained from materials such as wood, rags, esparto, straw, pulp or used paper, and various types of machines are subsequently used in the manufacture of paper. In fact, even though the professionals who carry out the work can be the same, the manufacture of paper pulp is included within the basic chemical industry, whereas finished paper and cardboard are more specific to the manufacturing industry. Their work is usually performed at large plants, where paper pulp is produced and paper is processed, although there are some companies with lower manufacturing volume where this work can be performed by experienced paper manufacturing operators, with technician being the natural progress to a higher category.

Tasks

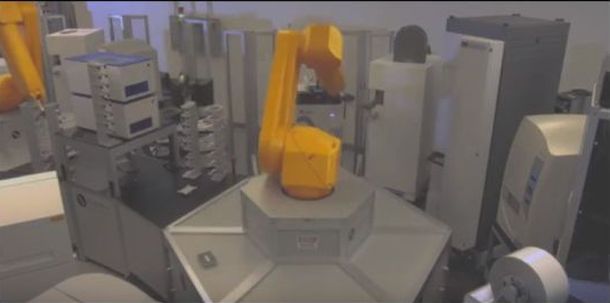

- Operate machinery for the production of paper pulp, paper and cardboard.

Prepare and operate manufacturing machines according to the required quality.

Direct first-line maintenance as well as cleaning operations of equipment and facilities.

Take samples for quality control and perform simple tests on prepared pulps, papers and cardboards, checking compliance with intermediate product specifications.

Prepare glues and surface treatment baths at machine for paper and cardboard, while respecting conditions for proper implementation.

Comply and enforce standards of good manufacturing practices and safety and environmental standards in chemical processes. - Perform finishing on papers and paper boards.

Finish papers and paper boards, obtaining required dimensions and optimising use of the product.

Adjust smoothness and conditioning of paper and paper board according to required quality.

Prepare papers or cardboards, as a finished product, for storage or shipment.

Operate machines, equipment and facilities in accordance with established safety standards. - Prepare and fine tune equipment and auxiliary facilities for the papermaking process, keeping them in good operating conditions.

Transport solids and liquids required for the papermaking process.

Supply or evacuate air, steam or other gases for the papermaking process, as stipulated.

Establish and maintain the thermal conditions of the process using generators, heat exchangers and cooling units.

Obtain water vapour, adequate for the process, operating steam boilers. - Oversee the paper pulp mill process

Assist in starting up and stopping continuous and discontinuous processes, according to established procedures and synchronising operations.

Mark the control points necessary to reach the operating regime.

Measure process variables with established instruments and frequency and adjust different parameters using the control panel and managing equipment indicators.

Analyse the paper pulp and the closed water circuit of the company.

Control the process according to the production plan.

Perform quality control operations throughout the production process.

| Catalan | Beginner

| Catalan | Beginner | English | Advanced

| English | Advanced

Open

Open

| Catalan | Advanced

| Catalan | Advanced