Assembler for special technical fabrics

Other denominations

Assembler

Description

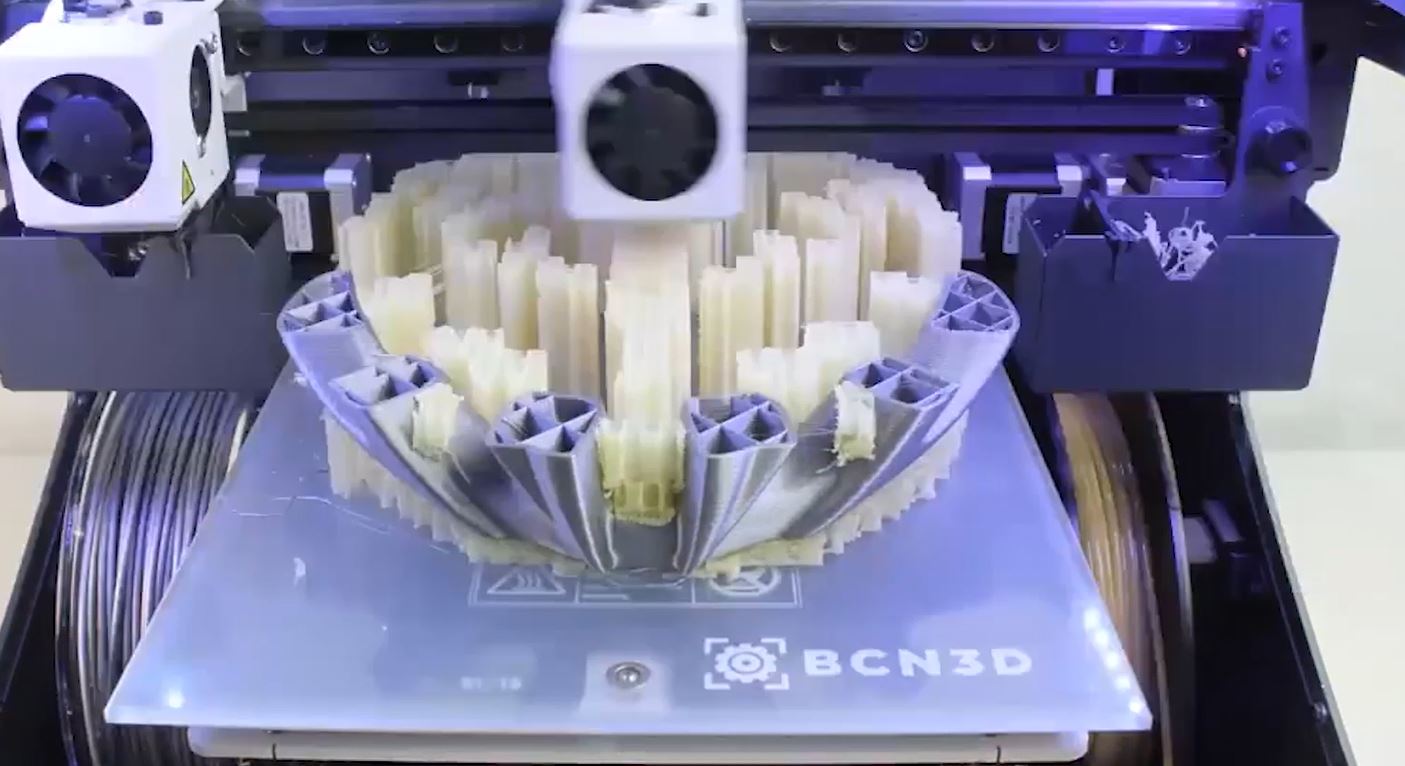

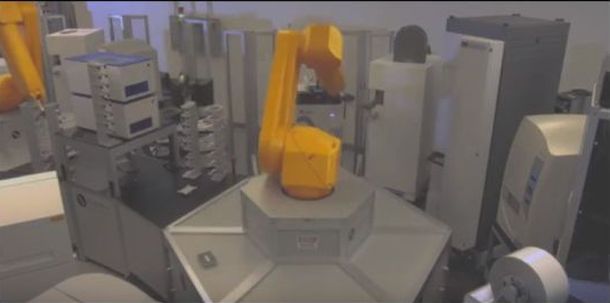

The economic recession affecting the textiles-clothing has led some companies to seek out other companies and other market niches. One example includes companies that have explored the prospect of technical fabrics. Some examples of these include geotextiles (applied to civil engineering), interior fabrics (applications in the automotive and aeronautics sector) or fabrics for personal protective equipment (resistante against fire, water, slashes and molten metal splash). Technical fabric assembly workers in the textiles-clothing industry are operators who use a variety of (normally technologically advanced) techniques to assemble the parts of textile articles. The job involves a large amount of independence and responsibility, and the professional must apply the necessary techniques and procedures in order to achieve the quality standards required.

Tasks

- Interpret technical specifications and production notes to organise the work.

- Change, adjust and reset machine parts and verify materials to prepare them for assembly.

Prepare the elements of the assembling machine according to the technique required (seam, adhesive, stapled, thermofusion, heat-bonding, ultrasound bonding, high-frequency bond,...) according to the technical data sheet and materials to be joined. - Perform and control assembly operations of components and trimmings, ensuring ideal operation of production, material flow and the production of garments or articles with the planned quality.

Systematically verify the following parameters: That assembly is executed, taking the hardness, length and thickness of the material into account, as well as the joining method that must be employed in the pre-established sequence. That joining is done neatly, aesthetically and in the timeline established by the company. That decorative items are added depending on the design - Perform basic machine maintenance to prevent stops or restore production.

- Take charge of detecting failures in direct production machine parts and replace the broken or worn parts to restore normal operating conditions safely and efficiently.

- Provide technical information on the work done, results and product quality, in order to contribute to production plans and quality management.

| Catalan | Beginner

| Catalan | Beginner | English | Advanced

| English | Advanced

Open

Open

| Catalan | Advanced

| Catalan | Advanced