Polymer technician

Other denominations

Materials development technician; Polymer engineer.

Description

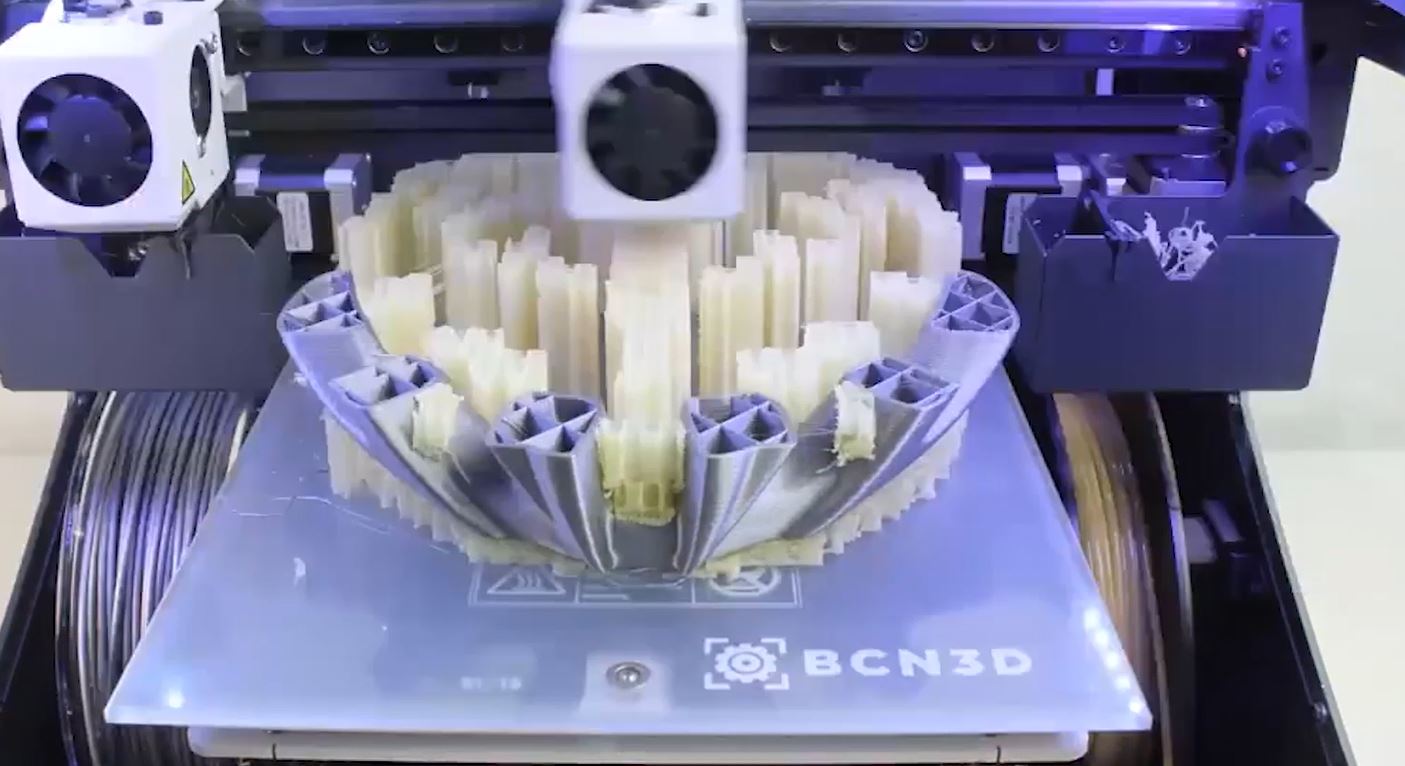

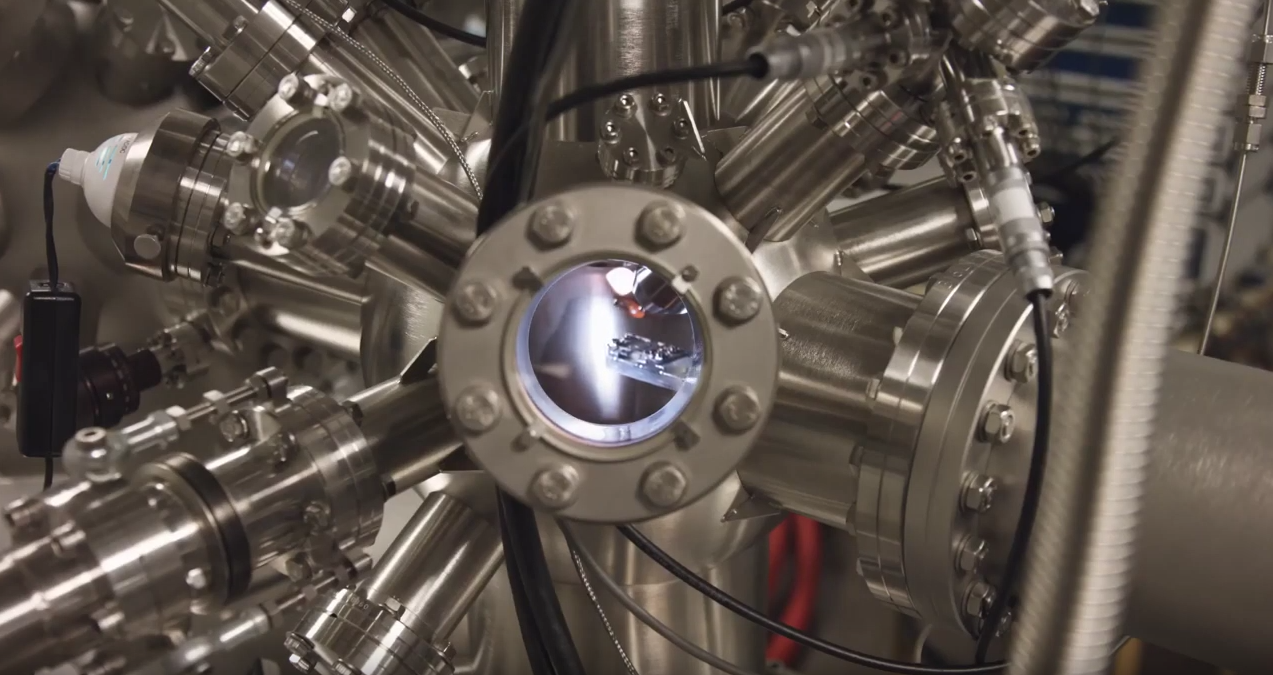

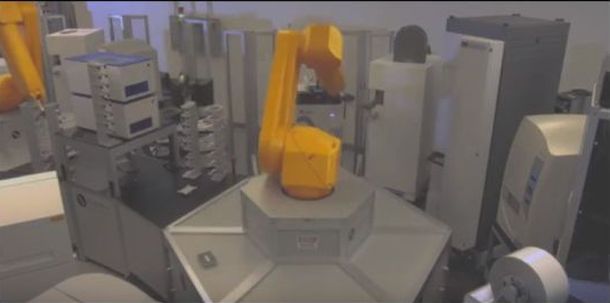

Polymers are present across all the fields of society, and are fundamental for sectors such as agriculture, the manufacturing industry, the food industry, medicine, telecommunications and transport. Polymer technicians are responsible for designing and developing polymers, from production in laboratories and industrial plants to use in the manufacturing industry, where they transform them into the relevant final products. This work includes composite materials or specialisation in specific types of materials, such as graphite, metals and alloys, ceramics, plastics and other polymers and natural materials, as well as research into recycling and the application of biotechnology in the production of biomaterials. Although this occupation is normally performed by highly qualified staff, particularly where R&D is concerned, it may also include operators specialising in the processes for obtaining polymers, who normally work under their supervision. Polymer technicians primarily work in those basic chemical industries in which plastic raw materials and rubber are used, as part of R&D, technical services and process control departments, although they may also be employed by public organisations and universities or other industries dedicated to adhesives, coatings, synthetic fibres, materials for the automotive industry or aeronautics or biomedical applications.

Tasks

- Undertake the design and development of new materials and products for the company.

Review the plans for new products and make recommendations on the selection of materials on the basis of the design brief, such as strength, weight, heat resistance, electrical conductivity and cost.

They are responsible for formulating and synthesising new polymers on the laboratory, pilot and plant scale.

Improve organic and polymer synthesis techniques in order to boost the development and characterisation of new products.

Perform tests on the physical and chemical properties of the new products.

Provide technical advice and support for the development of new products, particularly in relation to the applications required by clients, and search for the cause of possible issues that could arise during their use.

Draft the documentation for the different tests, keeping the database for these up-to-date. - Devise and constantly improve the polymer manufacturing strategies.

Decide on the efficient use of the resources available, in particular materials and machines, determining the most suitable methods for the manufacturing and processing procedures.

Design and lead the tests and process control procedures for the production of polymers.

Resolve issues that arise during the chemical process.

Assess the technical specifications and economic factors associated with the targets for the process or product design.

Record data relating to the development of the production process and ensure that the target specifications are complied with. - Monitor the quality of the materials and assess their deterioration.

Supervise testing on raw materials and finished products to ensure their quality.

Analyse data relating to product flaws and the results of laboratory tests to determine the causes for issues with materials, developing solutions. - Train supervisors, technicians and operators on new materials, machines or processes.

| Catalan | Beginner

| Catalan | Beginner | English | Advanced

| English | Advanced

Open

Open

| Catalan | Advanced

| Catalan | Advanced