Process controller

Other denominations

Process Engineer.

Description

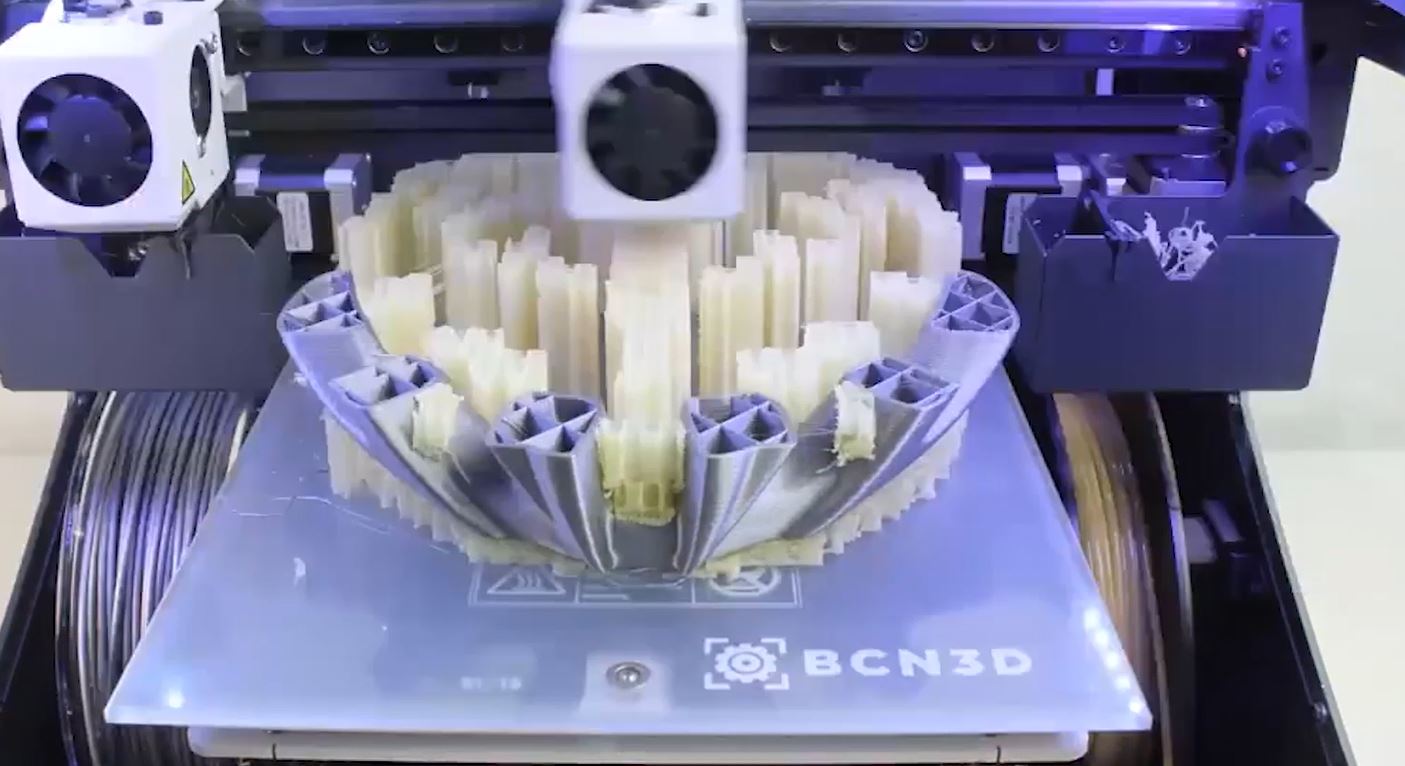

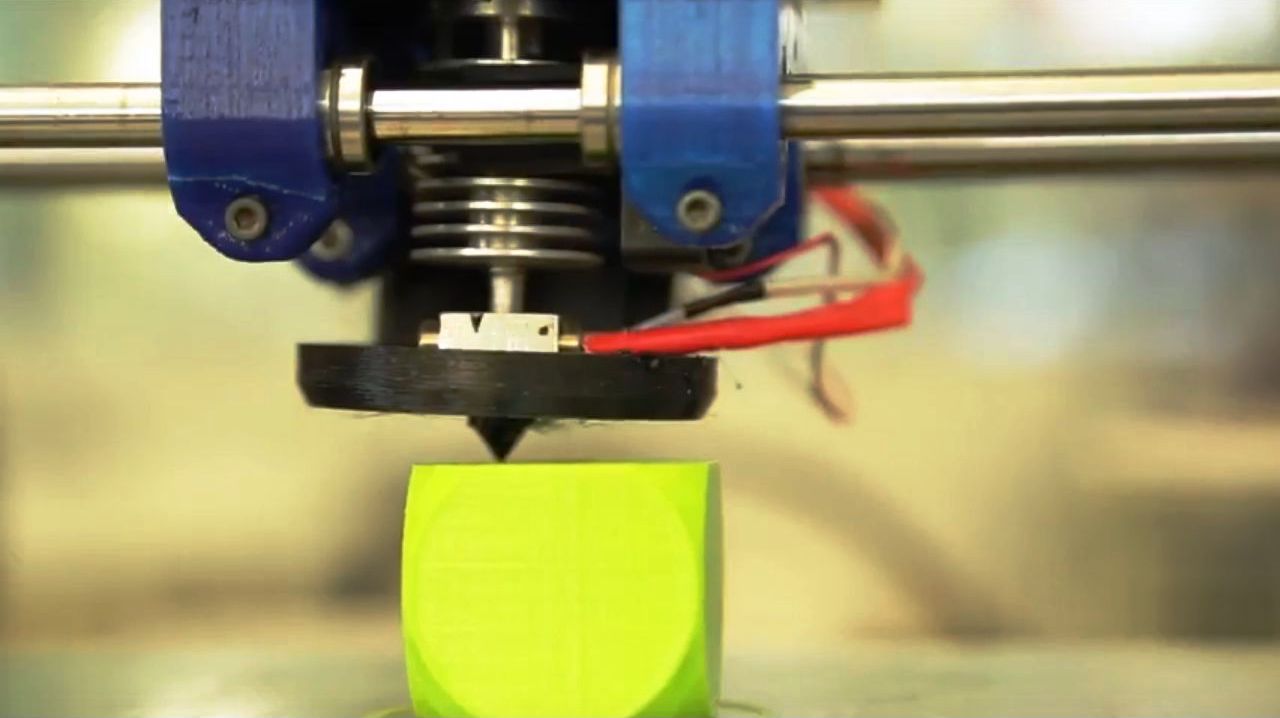

Companies have an ongoing need to improve processes to remain competitive at an international scale respecting sustainable development. Advanced control systems allow factory control and makes easier processes and workers full security.

Basically, process controller is responsible for organizing and controlling a production plant, assessing the different stages of the production process, proposing the optimization of manufacturing procedures and monitoring the regularity and improvement of quality, as well as improving environament issues. These professionals often work in manufacturing and processing companies for energy storage, coordinating work teams consisting of maintenance, quality control and production staff.

Tasks

- Coordinates the production and control for the industrial process. Executes the manufacturing plans, ensuring compliance with the levels of productivity and quality within the established deadlines.

Participates in the organization of the production of a process or of the whole factoryt, establishing the production program, and the rational use of available resources.

Prepares standard working procedures for the various operations, including commissioning, shutdown and ordinary operation process. - Monitor the plant efficiency, productivity and safety, making comments, measurements and understanding data from the rest of the technical and operational staff.

- Records data, prepares production reports and develops the operating budget for its area of responsibility

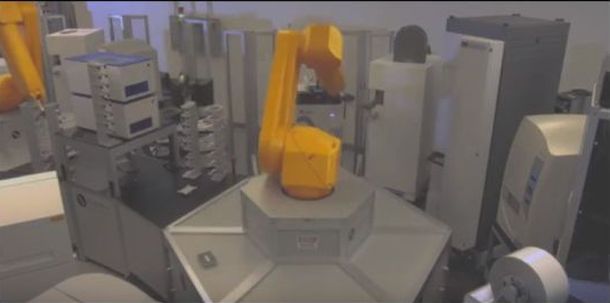

- Manages the PLC (Programmable Logic Controller), an industrial digital automatic system that has been adapted for manufacturing process control, such as assembly lines or robotic devices, or any activity that requires high reliability and ease of control, programming and diagnosis of errors in the production process

- Review the design, specification and implementation of new processes, from product development to production stages, in accordance with quality objectives of production, cost and delivery.

- Is responsible for the development and improvement of production process, evaluating different operations and manufacturing systems for final production. It studies production facilities dimension in order to increase production capacity at the lowest possible cost.

- Controls the right condition and operation for equipment and facilities, and has the resolution of any detected faults. He/she Participates in the planning and management of plant assemblies and authorizes maintenance orders.

- Collaborates in the design, installation and control of new production units

- Supervises and coordinates the activities of factory workers.

- Monitors quality improvement on a regular basis. Participates in security audits and programs and provides emergency response. It complies with rules on proper manufacturing, safety and environmental regulations for industrial processes. It assumes responsibilities in risk assessment, studying process potential dangers for the workers, citizenship and the environment, together with field specialists.

| Catalan | Beginner

| Catalan | Beginner | English | Advanced

| English | Advanced

Open

Open

| Catalan | Advanced

| Catalan | Advanced