Designer of models, mock-ups and prototypes

Other denominations

Modelista, maquetista

Description

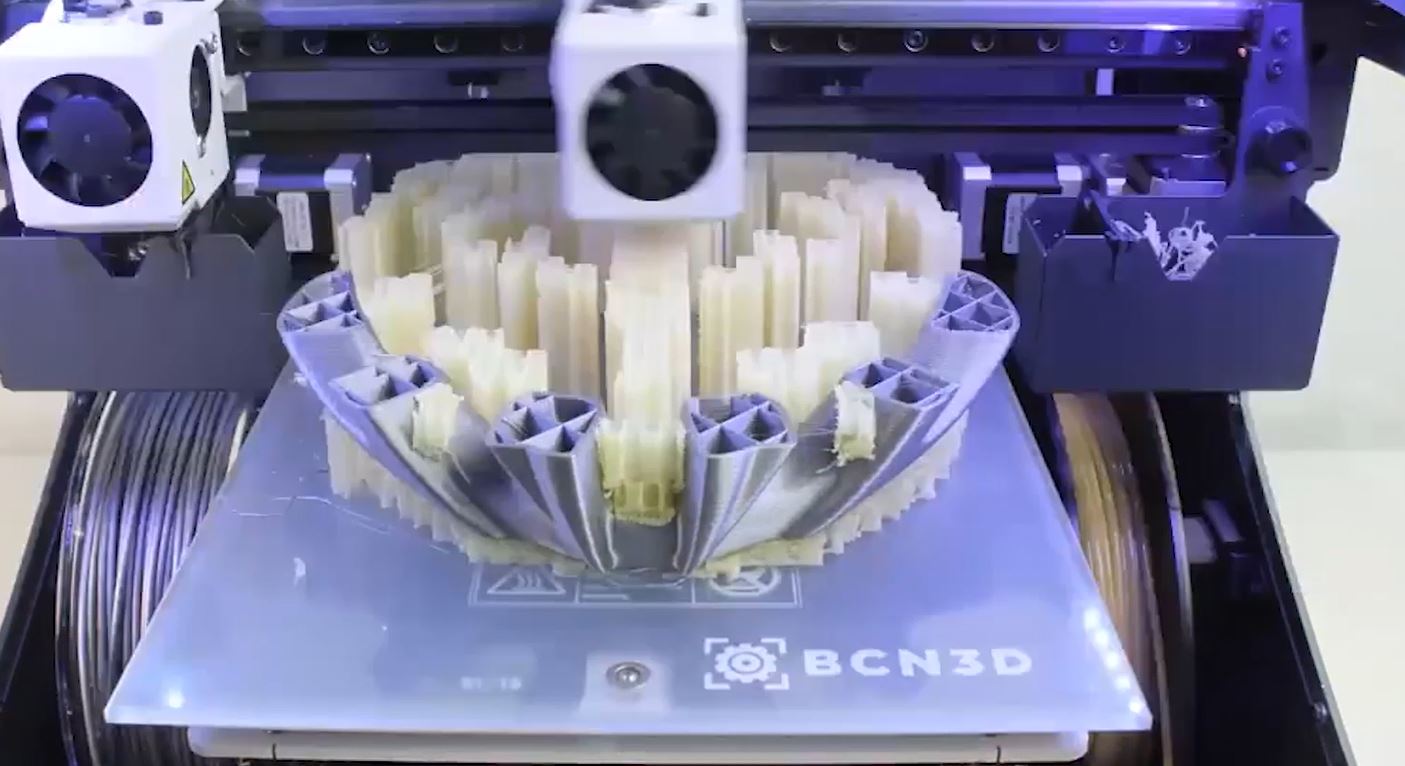

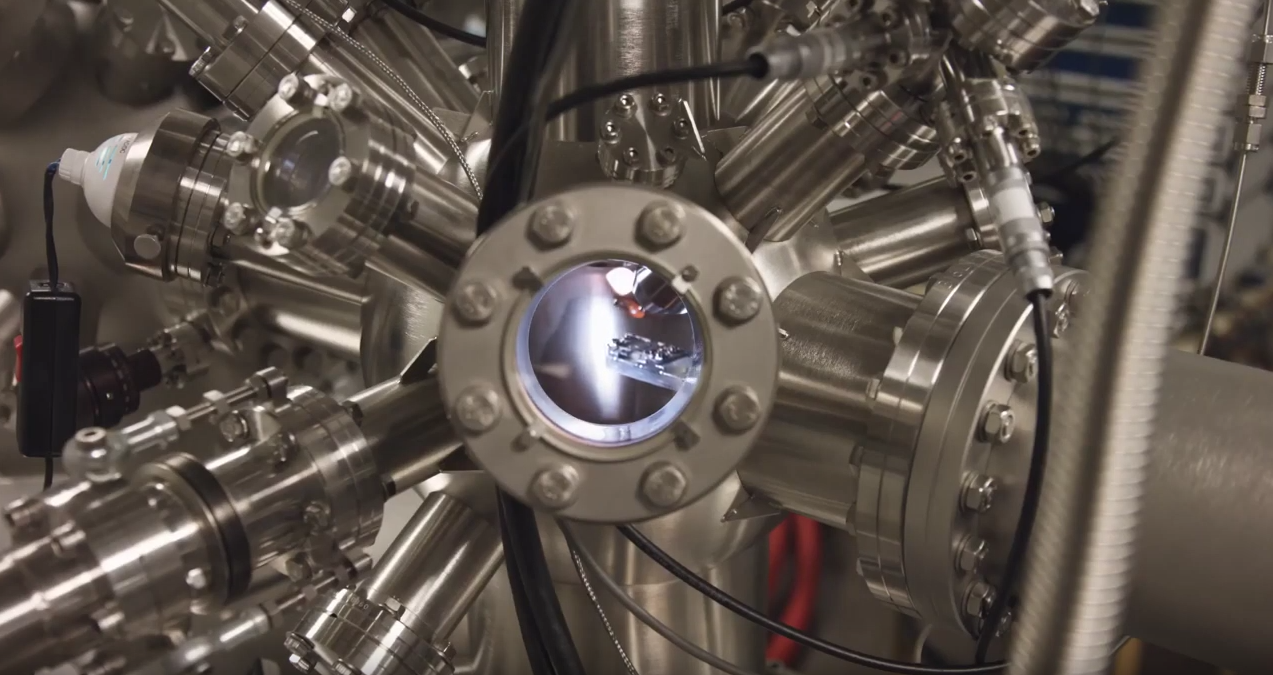

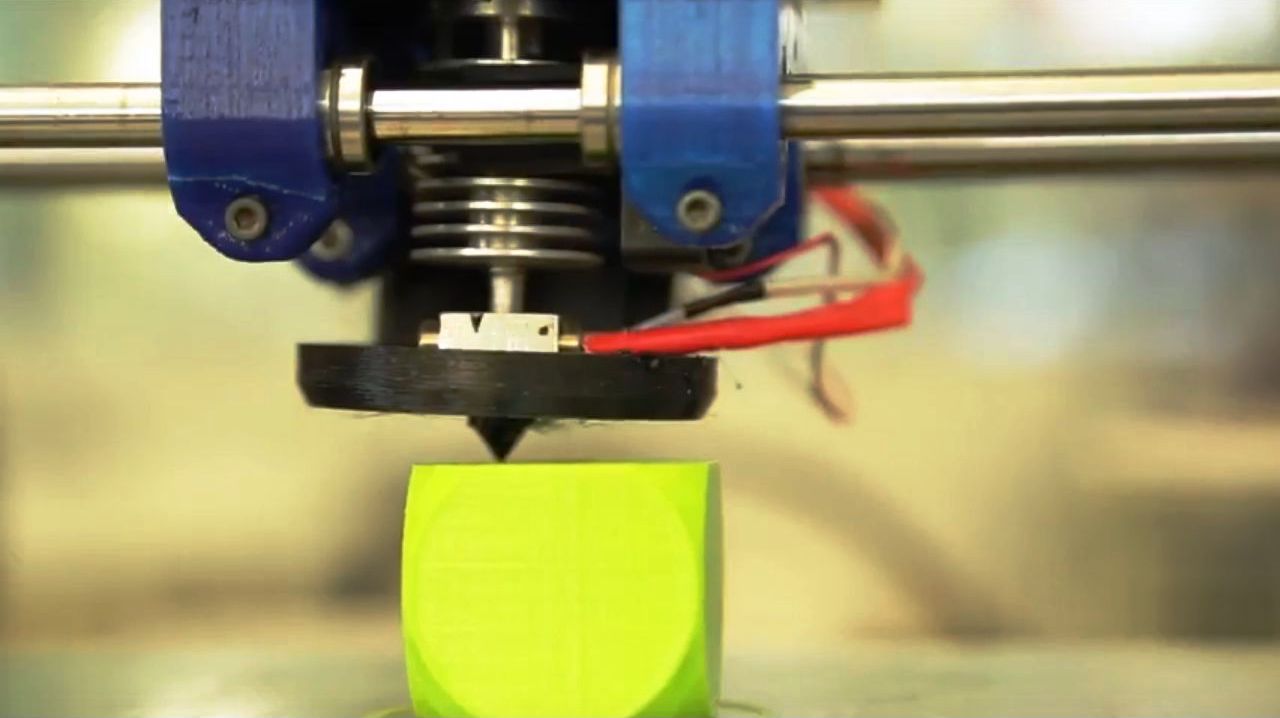

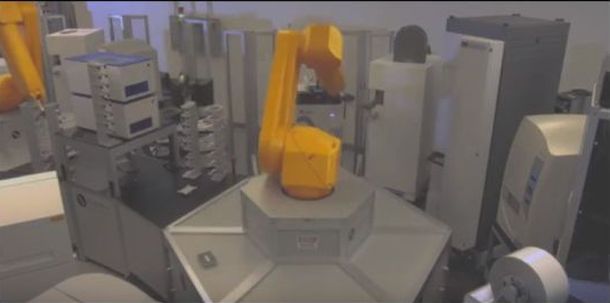

The designer of models, mock-ups and prototypes is in charge of interpreting the industrial or niterior design project and carrying it out volumetrically in order to validate it before its final production or creation. The designer needs to perfectly understand the design plans and interpret them based on the technical drawings and digitised data. In addition, they are familiar with the manual and technical tools for the volumetric representation of the project. The model, also called the master or mock-up, is the industrial piece on which the final production mould is based. The model or mock-up can be made of different materials (resin, polyurethane foam, etc.) either manually or through numerical control. This makes it possible to validate the product's volume. The specific model in the fields of architecture and interior design is the mock-up, which makes it possible to perfectly understand the space design plans that have been drawn up. On the other hand, the prototype is basically used in the industrial field. It is a more precise product than the model or master. The prototype is functional; it is created so that the other components of the product can also be assembled and to see not only the volume of the product but also its operation and creation. It provides an almost perfect view of what will be the final reality of the product, since it can be made with the material that will be used in its final production or with an almost perfectly comparable material. The prototype is made always with numerical control.

Tasks

- Analyse the design project.

Before creating the model, mock-up or prototype, the designer analyses and studies the plans based on the materials presented by the industrial or interior designer. This material or documentation can be based on technical drawings, digitised documents, 3D images, etc. - Create the model, mock-up or prototype.

Create the model by hand, rapid prototyping or precision machining tools. Rapid prototyping is a set of technologies that makes it possible to create prototypes in less than 24 hours, always based on a CAD file. - The prototypes are created based on numerical control or rapid prototyping. This system makes it possible to significantly speed up a product's development. There are various rapid prototyping technologies: stereolithography (use of UV laser), SGC (solid ground curing), FDM (fused deposition modelling), SLS (selective laser sintering), LOM (laminated object manufacturing) and DSPC (direct shell production casting).

| Catalan | Beginner

| Catalan | Beginner | English | Advanced

| English | Advanced

Open

Open

| Catalan | Advanced

| Catalan | Advanced